A quick update with progress....

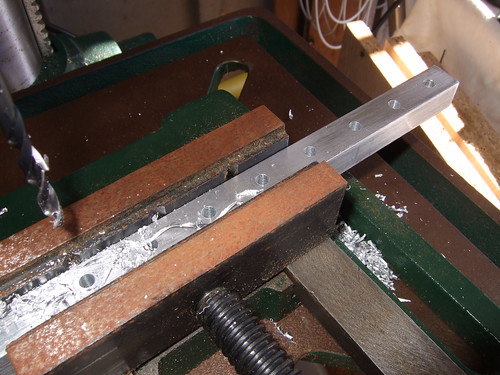

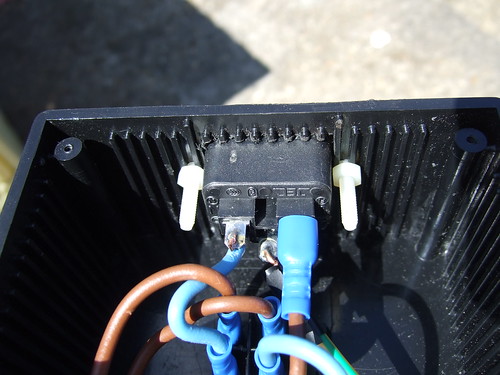

The feet I bought are rubbish. I've finally had to face that. Anyway, accepting that fact has made me rethink the false bottom. Rather than use those small aluminium blocks, I've used full length rails onto which to fix the false bottom.

False bottoms fixed

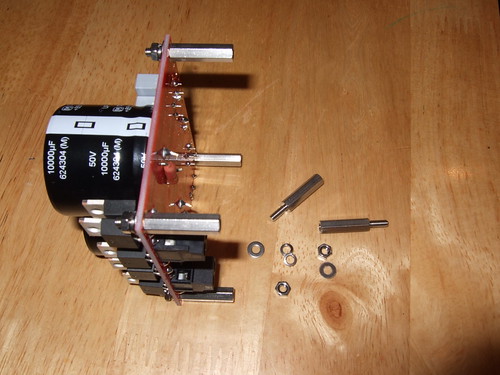

I needed to lay the components out on the false bottom to decide where to drill the holes to secure them in place. The first step towards this was to attach the standoffs to the PCBs.

Fixing stainless standoffs to one of the Power Supply Units

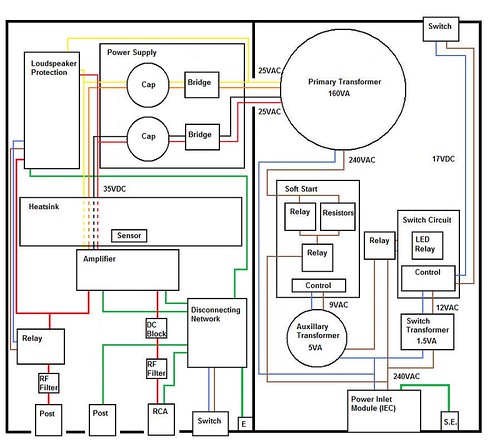

Once all the standoffs were in place, I could start to arrange the components onto the false bottom until I found an arrangement I liked. The goal here was to minimise the length of the interconnecting wires and to keep the audio signal path away from the noiser elements of the amps e.g. the transformer.

Laying out the components.

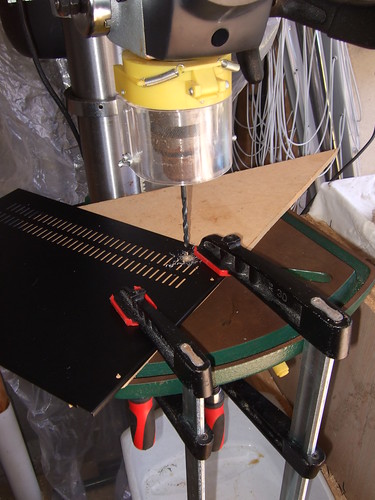

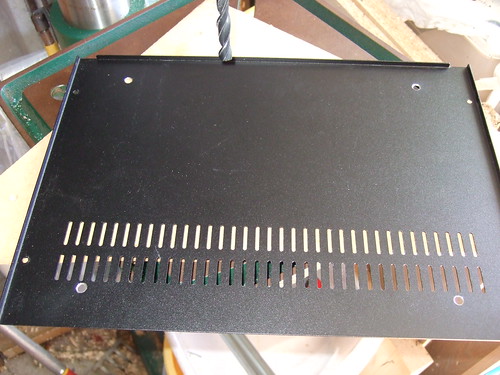

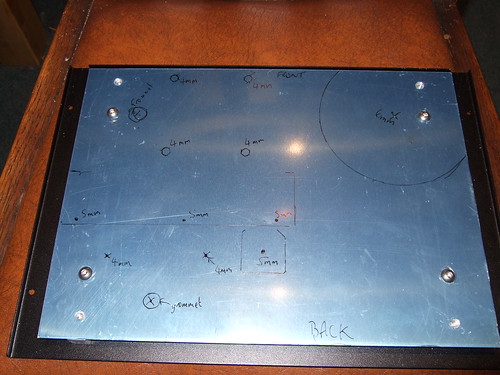

Once I was happy, I marked up the false bottom for drilling.

Marked up false bottom.

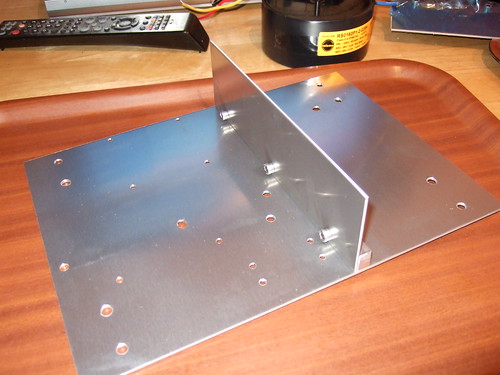

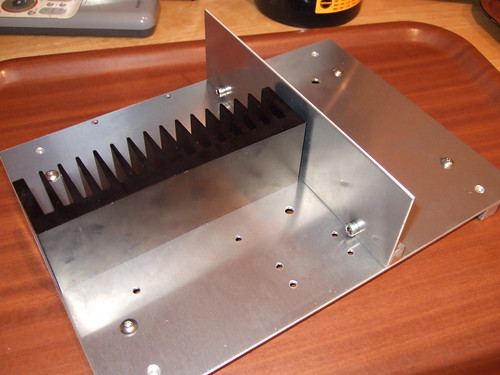

The drilling, deburring and tapping of holes actually took some time. I clamped the two false bottoms together, to arrive at a matching pair. So, once the drilling. deburring and tapping was finished, I thought I have a trial build.

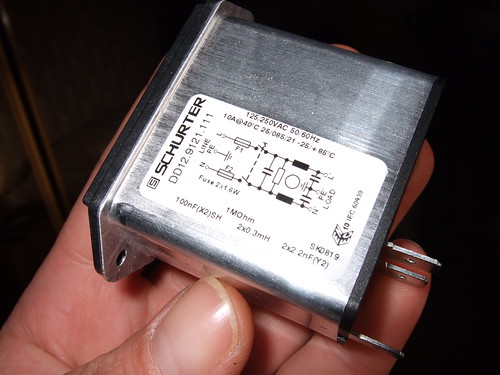

Firstly, I bolted a chassis divider to a length of aluminium bar, which I then bolted to the case. This provides additional shielding for the more sensitive audio components from the power inlet and transformer.

Internal chassis divider.

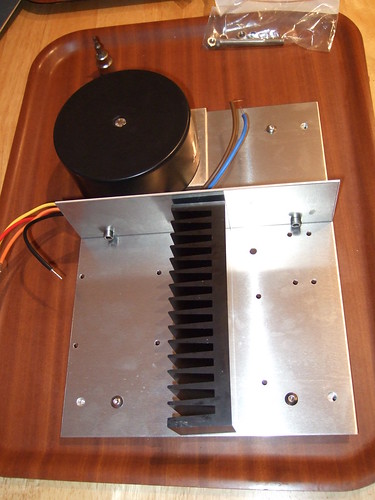

The next to go in was the heatsink. This has been drilled and blind threads tapped into it from underneath, allowing the heatsink to be bolted to the false bottom.

Heatsink in place.

I put the transformer in next. This sits on top of a little mounting plate of 5mm thick aluminium, which allowed the wires to remain untrapped by it's own encapsulating case. A single bolt goes through the middle of the transformer, mounting plate and false bottom.

Transformer in place.

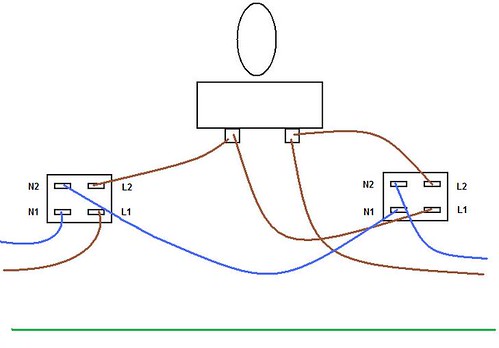

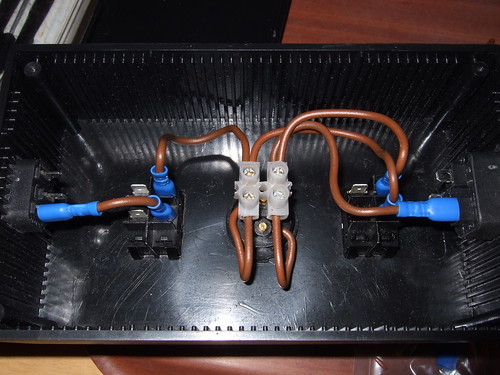

And finally, I fixed the PCBs and disconnecting network (more on this later) onto the false bottom. Clearly, it still needs to be wired together and there's one or two additional components which may yet be required (soft start circuit, DC blocking caps and high and low pass filters, etc), but essentially, the core elements are in place.

All major components in place