The SL-1200 series was developed as a special project by Technics parent company Matsushita in an attempt to solve many of the problems related to the difficult task of turntable design. The task included minimizing acoustic feedback, unwanted resonances, wow & flutter and speed errors.

This was achieved by designing a remarkably heavy plinth made of a non-resonant composite sandwiched between a cast alloy top plate and a solid rubber base. In addition, the adjustable rubber-damped feet ensure that the Technics SL-1200 series are well-insulated against acoustic feedback, which can be a serious problem when operating a turntable in close proximity to PA loudspeakers (a common situation for DJs).

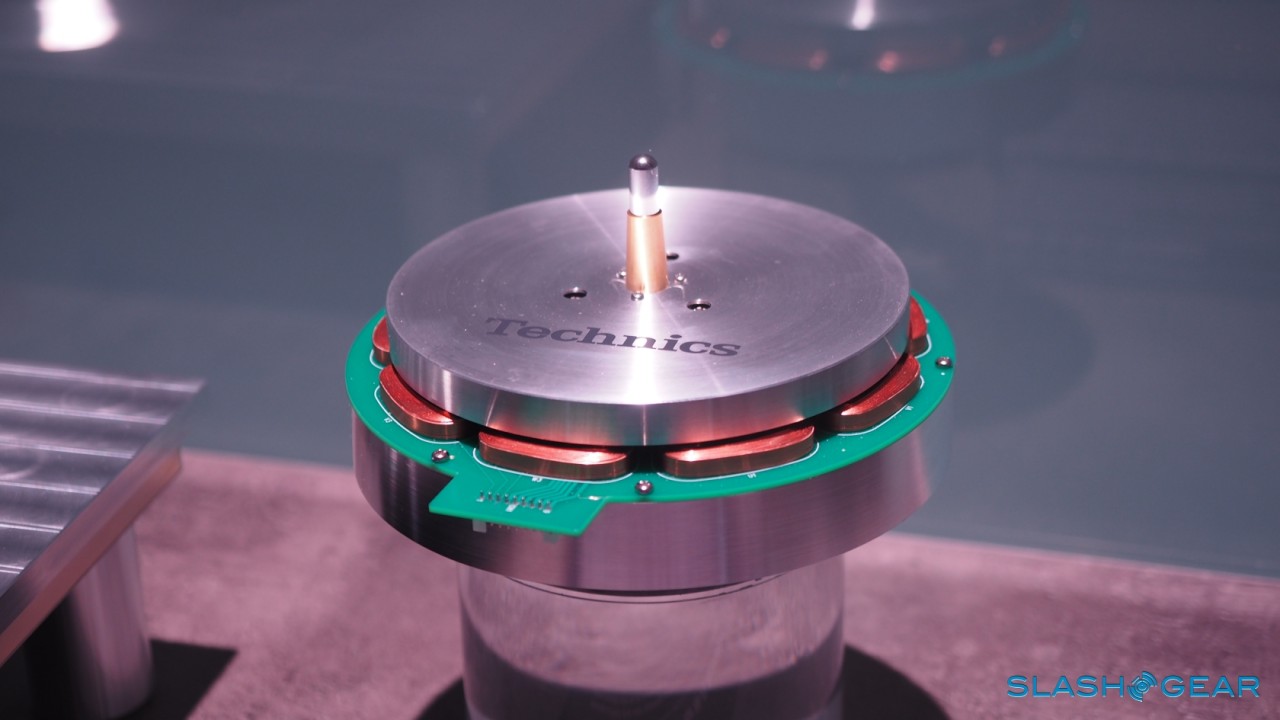

The drive system designed by Matsushita is of the direct-drive variety rather than the more commonly found belt-drive type. This design was developed in order to virtually eliminate the problems of wow and flutter and produces a very quiet turntable which, for a direct-drive turntable, has minimal motor and bearing noise, (although the bearing rumble does tend to become characteristic in well-used turntables). This was partially achieved through the fact that the SL1210/1200 was the first (and only) turntable to actually make the platter a part of the motor mechanism as opposed to just being attached to it via screws or magnets as is the case with most direct-drive turntables. On the underside of the platter there is a large magnet which, once placed over the spindle, surrounds the coils and forms the motor drive thus eliminating loss through power transfer. The SL-1200 utilizes a Frequency Generator Servo Control Quartz Lock system that is claimed to produce the most accurate and consistent speed possible. The system is immune to static and dynamic stylus drag which would otherwise cause unwanted speed variances that change the pitch and tempo of the music.[11] Due to these strengths the SL-1200 lends itself to both Hi-Fi reproduction and demanding DJ usage.