iQ Speakers

New member

- Feb 24, 2013

- 129

- 4

- 0

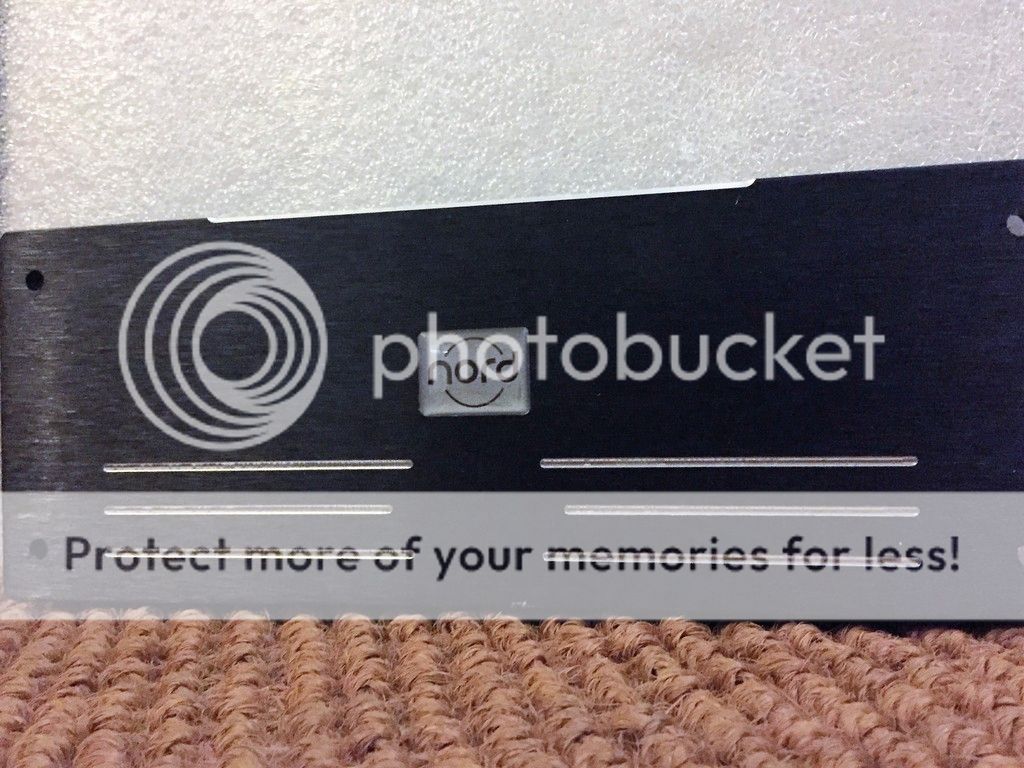

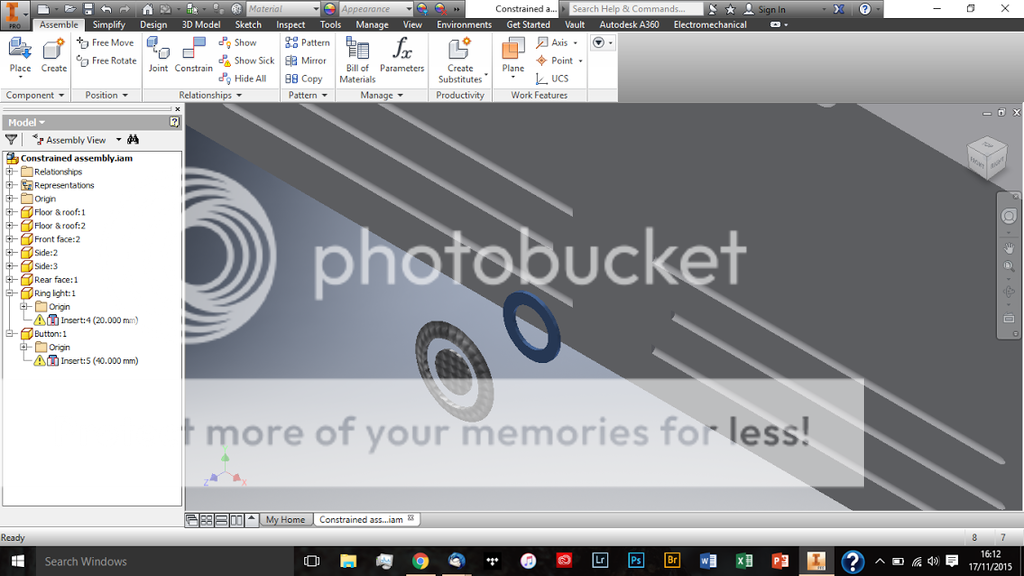

OK here is the final layout...

Its not finished the switches I ordered were on back order so there will be mains wiring to the front panel and some power for the LED. Much neater this way and cables much shorter. Cable routing and loom will be next once the switches arrive. XLR's in place some high quality Switchcraft Gold plated metal bodies courtesy of a great little supplier Action Hardware who are also the CHK distributor in the UK the mains IEC switch input come from them as well. XLR's sounding much better.

Next up is design the packing and get it on order.

Sounding wonderful. Enjoy.

Its not finished the switches I ordered were on back order so there will be mains wiring to the front panel and some power for the LED. Much neater this way and cables much shorter. Cable routing and loom will be next once the switches arrive. XLR's in place some high quality Switchcraft Gold plated metal bodies courtesy of a great little supplier Action Hardware who are also the CHK distributor in the UK the mains IEC switch input come from them as well. XLR's sounding much better.

Next up is design the packing and get it on order.

Sounding wonderful. Enjoy.