Have you tried waxing your components today?

Page 2 - Seeking answers? Join the What HiFi community: the world's leading independent guide to buying and owning hi-fi and home entertainment products.

You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

Cpt.Issues

New member

- Oct 17, 2010

- 22

- 0

- 0

Don't know about wax but on the subject of weather proofing boxes I came across an amp on the internets which is available with hammerite paint finish as standard..

I really dont understand where all these mickey taking comments are coming from!!

I read somewhere that if i spent 50 quid on a USB cable i would notice a difference in sound quality over a 2 quid cable for my hifi.Now,that sounds absurd to me as all it does is transmit a digital signal!

So why an earth would forum members think i was joking when i think that it may be possible to get an improvement,no matter how marginal,by getting an extremely slick surface on my components

which are situated directly in the path of my large floorstanders?

When i say slick,i mean slick.I actually spent a lot of time using an automotive cutting compound to flatten the paint surface off properly before i applied three layers of black wax.The casework now has a mirror finish that looks absolutely stunning!If i do get a SQ improvement it will truly be the icing on the cake :dance:

I read somewhere that if i spent 50 quid on a USB cable i would notice a difference in sound quality over a 2 quid cable for my hifi.Now,that sounds absurd to me as all it does is transmit a digital signal!

So why an earth would forum members think i was joking when i think that it may be possible to get an improvement,no matter how marginal,by getting an extremely slick surface on my components

which are situated directly in the path of my large floorstanders?

When i say slick,i mean slick.I actually spent a lot of time using an automotive cutting compound to flatten the paint surface off properly before i applied three layers of black wax.The casework now has a mirror finish that looks absolutely stunning!If i do get a SQ improvement it will truly be the icing on the cake :dance:

A

Anonymous

Guest

KiwiMoto said:When i say slick,i mean slick.I actually spent a lot of time using an automotive cutting compound to flatten the paint surface off properly before i applied three layers of black wax.The casework now has a mirror finish that looks absolutely stunning!If i do get a SQ improvement it will truly be the icing on the cake :dance:

Ooo.....shiny.

Sorry Mr Duncan! 😳

CnoEvil said:Is it more effective if you're from Brazil? :shifty:

I saw what you did there, very good. So what was her reaction when you called them by that name?

Overdose said:KiwiMoto said:Hi,i've taken all my components out of my rack today and used a premium grade automotive wax on the casework.The wax i've used is a black,coloured type that enhances the black casework. The end result is a lovely,glistening finish that protects the casework from corrosion and moisture penertation.I live in a close proximity to the beach so salt spray is a real nuisance to all household items and tends to discolour and rust things extremely quickly! The real upside though i think will be to test the equipment once it's all back up and running to see if i can notice an improvement in sound quality.I believe the slickness of the casework now could possibly help reduce vibration,and high frequency reflections. I am wondering if any other forum members have ever tried this,and what results they may have achieved?

Aside from the juicy dangled bait (i really hope you aren't serious about the last bit), silicone spray works well to protect surfaces and silicone is non conductive, so PCBs can be protected with it also, so you could give the case insides a light spray too.

This is also a joke right? :O

SteveR750 said:Overdose said:KiwiMoto said:Hi,i've taken all my components out of my rack today and used a premium grade automotive wax on the casework.The wax i've used is a black,coloured type that enhances the black casework. The end result is a lovely,glistening finish that protects the casework from corrosion and moisture penertation.I live in a close proximity to the beach so salt spray is a real nuisance to all household items and tends to discolour and rust things extremely quickly! The real upside though i think will be to test the equipment once it's all back up and running to see if i can notice an improvement in sound quality.I believe the slickness of the casework now could possibly help reduce vibration,and high frequency reflections. I am wondering if any other forum members have ever tried this,and what results they may have achieved?

Aside from the juicy dangled bait (i really hope you aren't serious about the last bit), silicone spray works well to protect surfaces and silicone is non conductive, so PCBs can be protected with it also, so you could give the case insides a light spray too.

This is also a joke right? :O

Not at all, silicone is a water repellant and is widely used for protecting against moisture ingress and the damage it causes, amongst other uses. It is also one of the compounds used to protect PCBs from the same. Being non conductive it will not cause any shorts. I would limit it's use to non dynamic components though.

And for the OP, creating a more reflective surface that sits in front of your speakers will most likely have a negative effect, although I don't know how you would quantify it. Sonically reflective surfaces are what you would normally try to avoid.

SteveR750 said:CnoEvil said:Is it more effective if you're from Brazil? :shifty:

I saw what you did there, very good. So what was her reaction when you called them by that name?.....

........ :silenced:

Anyway, I was only waxing lyrical. :roll:

eggontoast

Well-known member

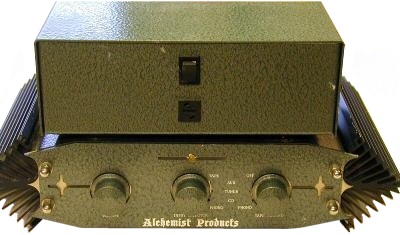

Rather than using car wax next time you might want to try some of this

data:image/jpeg;base64,/9j/4AAQSkZJRgABAQAAAQABAAD/2wCEAAkGBhQSEBQUEhQWFBUWGBUaGBgVGRgdHBoZHB8XFxcdGhgYHiYfHh0jHhcXHzAgIyopLC8sFR41NTAqNSYrLSkBCQoKDgwOGg8PGiwlHyQqLy4sLywsLCwsLCwsLCwsLCwsLCwpLCwsLCwsLCwsLCwsLCwsLCwsLCwsLCwsLCwsLP/AABEIAOEA4QMBIgACEQEDEQH/xAAcAAACAwEBAQEAAAAAAAAAAAAABgQFBwMCAQj/xABOEAACAQIEAwUEBwUEBgcJAAABAgMAEQQFEiEGMUETIlFhcQcygZEUI0JSYqGxcsHR4fAzkqKyFTRDRGOCFhckVFWD0iVFU3OTs8PT8f/EABkBAQADAQEAAAAAAAAAAAAAAAABAgMEBf/EAC4RAAICAgIABQMDAwUAAAAAAAABAhEDEiExBBMiQVEyYYFCoeEUkbEjUnHB8P/aAAwDAQACEQMRAD8A3GiiigCiiigCiiigCiiigCiiigCivEkyqLsQPU2/WoM2fwr9u5/CCfz5UJUW+ixoqik4rQckY+th++vB4sH/AMM/3h/Cosv5U/gYKKX/APpao95CPiDXeLiqE89QPpS0Q8cl7FzRUCLPIG5SL8dv1qarg8t6kq012eqKKKEBRRRQBRRRQBRRRQBRRRQBRRRQBRRRQBRRRQBRRRQBRUfF41Yxdvl1pexudNIdN9A8uvqaGkMbn0XOMzlU5Xc+XL51RYniGRuoUeC/x51VYnMOwBYsAg3JYgAfE0k597VY79nhYjNISAG303OwAUd57+G1Vs6Vjhj+oeMVibsDcm/jvVPj+JIIS3aTRofAsL/Ib1nz4TNMY7pKzQBFLtG14yIwrvrEY77r3CtxfvMoPOl3IctinhxRYv28cXbRqNIVkQqZ7nmW0FiNrdwnypRD8QlxFGj4r2l4RbWZ3I+6h/VrVXy+1mG+0Up+KD95rxHhcHBPGzx4OJGhLyK8glBOrUkKli7I5R0V5dI9x9AuN6DP8VHJgcLFGyTSIQWEcTqVGnRoRuzAK90MzEks73sLbqRm88y+HtaiJ3hkt4XU1Ih9qWFZu92iX8VBH+EmlnKsbHHi8TJFDLgkkhZIGZZJDBIez72rTq3CyLqUEr2m3Kp+Gx+Af6V9InWSfELIglkgCBRHD9W/PuPJNpOoAkiPvaS5qaHnzHDAcX4aWwSdCT0J0n5NberzCZqybo5XzB2+XI1n2H4VwGIjijj06lbBRSSxkggmNp8VIzF2R1CRyjZQVYDmOcfDcNyhgcvxWxMS9m0iyKskjS90yR/VkLFEZmNtl2IvUUXWdP6kbTgOMjylXUPvLsfiDt8rUw4LMo5RdGB8R1HqDvX57w/GWJh/1yBtALDtIxt3XaIk9La0deYvpNqbso4jjmAaGQEjwNmX1HMUtrseXCf0s2CilLKOLCCFm7w++OY/aHX1pqhmDAFSCD1FSmc8oOPZ7oooqSgUUUUAUUUUAUUUUAUUUUAUUUUAVBzPMhEvix5D958q95jjxElzueQHiaVZ8RqJZjdj/Vqhs3xYt+X0eZ8cS5LG9KPF/HUOF7vvy9IweXgXP2R+Z8OtUvHftA0OcPgzqlJ0s676WO2lPvPfby8zyocm4SdI5Z8TGjykWRMUZEVZdffScsUIdkBKMW0MbjVqFqivk2nlUeIFJmOcYvMJD78mkMwjjUlVVdydI6Dqx+dOWUy4KDCQYyNUV4wsilmGszx92SBu/qbtdd1ZUCooQ7m9U2RcFzy4ho8BI2sALNPG2mBFdFMsetSS5DFl7pIYL8a0HLuH8uya1x9KxlgRcAsPAgHuwr5nvHpflUtpHI5e8mU/D/DeNliiTBRyYWJRiNM+Mb61RMYiwhWMBgAItmNrmRjteps/AWWQSs+PxJxE7Es6JZbsef1MA1D4kCo+f8bTS/20wgjPKONitx+J9nf4aR5VX4YKF7lrHcabWPntz9a5Z+IS6VnFk8XGP0qxhgz7AYfbC5au3JnWNPzbW/zrsfaNiPsYeBB5vIf8qrS21L2e5KZZdbSmONU3sTzBNzbkBYjes455Sfdfg514qc3y6/BoX/WTihzjw5+Mo/PUaJOPdYtPgYZB1s4P5SR/vrF8nyrt5yFLdkpuWOxt0Hqfypg4izeVZY4YDZ33J26kgDf0JrRyyKWqlf4NpTyqSipX+B3mw+S4j+1wz4NjfvorKBfY96EslvUCvH/VrKsD/wCiscksTdr3JNJsZFWNyJY7gMVXTuBYFuVzSFPm2Lw1jMqSJe2pdj+X7xTJgMQCFmjLRswDB0JVtxfcrz9DcU89x5kuPsT/AFMo05q18o+5xnOLhxU7TRHBYjE9hBEWscPFDq1zPrN1cl9yCDYSSV5zXhWMzN9ED4YwJrknYSgaACoZkRWDGVxqVoSV0arqNFNOC40fQYsbEuLhYWJ0rrt+JD3H+Gk+pqNNwXbRi8klEixuJPosjNpEqqyra5DKy6z9W9uZ3sbHeE4z6OqGSM+YsX8HxdJh5mw2OASRG09ovuE2BFyNtwVNx0YXArQ8kzxoTdTcHcrfYjxHn51nTthMRHKcT2w+hxSMcNIWRlZroZJJLXlxEkxiv7oAdfeCWpX4V4xbDkJKS0X5p5r5eXy87NfB1wyp+mZ+q8vzFJkDIbjqOoPgalVlvD+eFSJYmBUgE791lrSMuzBJow6G4P5HwNE7M8mPR/YlUUUVYyCiiigCiiigCiiigCvEsgUEk2AFzXuqTPcVdhEDYbFv3D99C8I7OitxmOEjFnvbko8B/Gs59o/GfYoYMObSuO+w5xofD8TfkN+ZFOHEOdx4WB5D3yB3RyDMfdHz/IGss4eytp52xM0RxChizxkN9dcN2nZn3WdLqwjvc2AF7GqnVklqtUQMHwdi8NHDi44VnBEvaRsquqqByazHZo2J1CzKVbkVvTbw/lk+ctq1TwYGwWQs7F8R7p7MkHTIEIt2xUMRbVqYbecFwzFjMS2DwihML9RNiZUYlWst07JX1NE5LulixNgb+7amTi/OVRPoWFAjijGiTRsLAf2SnoAPfPPfTe5e0Skoq2cU5qC2ZzzfipIYxhctVY407plQCw6ERX2ZvGQ335XO4Q48wErSxQvaRd2dgWuSSGO5uxvzY359alRY6I+7Ih9GWkbHa48bIYb6gzMNO+1tR9RYnauVXlbvj4POUpZ5O+Pj+TnmAZHkScM0lxZyx2F73t1BHLwph4Xz+JYVidtJBaxb3bEkgA9OfWvJg/0hErhTFIhA1Ed0jqAeZtz8j61Zy8OwaAZQCQO8+yX8zpsKmeSLjrLsnJkg46T7+x3xU8jNH2JjK6vrLkE6duVvj+VV3FuDnkRUiF1Ny4BANx7vPpz+Iq94f4NkO+Fwz2b/AGjnQpHk0neI690EVbz8KtH/AG+LwkHkWLH/ABFKzjCSdxX9zKGLIpJxj188f9mYYTC46JCkaaQSTtovf1veu+bs8OKinZSyhEBI8QpVrnxub07y5VFyTMcIx8CLfmJTXLE8M4i10MM6/wDCff5MLfnWr3u2kdGmW7cV+BFz7O1xKpFEDuwJuLb8gPzJrnhIHxkugPpijUAeSjujbxNr3phnw/ZNaSIxN01qBe/g3unl0NUH0CWCRmiXWjAgr5HmCOfxFIySWqVP7kxqK1Sp+1k2JZcJpkjkE0BIDWNwBffbe3qPjTphsTJDL2sLmOQbXG4YfdkXky+R3HQg1n2XYR1LyMTh4rgEMCwa5sF0n3vjXeXNMVJiZFjfSVLWS4F9JtYA8z1+dRKDbtPle5nPHJyuLVr3NSzbJsPnkRuBhswjXn0dRyN+bxXtv7yEi/4kFclmleZMfHLLJgIoo0w8IVXZCWs2pVN4lG5cBida773qZw5nTTLqBMc8LA6l2KtvZgD6EFTsdwdjTxmeWrnOG1qEjzDC2I5aXG5AIbnDJY2vfS2oHrfbHkbesu0dOLLs3GXaM6yriOPCYgxRyNJg20FWbfs2dVZlJsAdJLKbAX03tzrWeFs77CUXP1b2B8vA1ludZxiMwiiwkadn2fexWu0aLLEj3ug7saKiu2wGpi+2wAncJ5hJFI2BxFu0jA0G9wVsGFj1Gkgj8J8qu0ejilstGfo9WvX2lvgnNu1h0Me9Ht6r9n5cvlTJV0c8o6ugooooVCiiigCiiigPE0oVSx5AEmk+eTWST7zb+lXvEE9kVPvHf0G/62pWznMhFEzHYBSbeQFzc+NVZ2eHjxZn3H+ZdtiFgQgJGRck2GttiSfBVI9LtXTD5rPgoXhbCsmk6O0jeZPrfsuDcoWNge7YMOYNROF4u2xLsZRFNsyMXVTrd1VmGrY6EaRrDc2FqZ8mw0uIx+FixLM/0ZHnftL6gC7fR0kFypYd1787ORuBSzCT2dl9hMIcsy0Lf/tc7Fnbme1canY+IjW/kSB96kjHZaskZQ6gpFjYm9r3N25m/Mnrc350x8V5t2uKcA3WK8a+osZT8Xsv/kis2z4zPMQFdRLYBb+8RYcgbeBrmn65ap9HnZryz1TqiqzvhPsh2kf1kXM25geNxzHn+VTMgyGImOeJ37re6wHPkRcevMU34OImFQyaCFClTY8gBtbmNq84fLz9XDAg1MQkachfc3PgoF2J8AetZPLJrVdnPLLNrRdnnA4GSWQQwJqci9uSovLU5+yt9vEnYA71cyNhcA1goxuMXmzbRQt4AbhSPAan8St665vjFwUZweEY9obHEzjZyxHuqR7rWty9xSoHeNwnZhqSB+xHeCnSAPnYdTa59anjHwvq/wAE3HB6Y8y+fg7cRcW4mSRFmlJV73VW7KMAEAgAG7Gxv3mOwpbx2aKv9iikb3kt3b7m1x7x28bedecXij3gheZCYR9YATrJYMF1ra5AHTY1wmxspSIKQWaOS4UD3lI2t0IHTxq+rdORdRbacufye455SrPoAuFNzcqR00oeWx3v4V8bFvZSsZR7++isNS72IK2IubbHpXXCh2dLB9CvzbUCQVa+rVzsbfOuWHws8atfUbxAL1sxYA8uoBJv4elT/Y0VL4sZ8Fns6oBJadGA1RzWJF+YD2/zBqn4bIIsQCcASsii74aU2NvFGJNh53Kea0oYHHMkkaSE7oQL33cOw5+YH6VfwyaWV0JR1N0ddmU+IP6g7EbEEVRyadT5RSWZr05OUR84y3toniIKOp91wQVcdGHTY/mCL0q4nCYlnjBiIlUj60X3AtpLMNja3PnWulRmcJZQq4+BRqC7CePe1vU3tf3HNr6W3WVkBF/12PhYg8jfa3SobeL6eUZyk8HXKfRBkkiwgZ2O8sl2PW7E9PuqLn/+1b4HMnglSeHd0vtfaRDbXGT4MALHoQp6Un5zkAmnLKyoum5JN9TG/IX26XqzyCNYYQjFFYE3IYWbwPyIHwqkqSUk+TF0kpxl6h14ziWKSDNcM7Lhp9H0koqkg2YQy2IJVgWKMR3huObGk3iTLSqRzwMrzYZVlnkZl7VxJ2QDOgFwNbsR2hEhWUXFhTxwJi4sTHisulKtHKjOoBBsGIWYC3KzFJB5s3hSNHLKiy4fFrPizBKYDEXCQBtLLG7aLySMFjdwQLqEBuRXoRltFM9fHPaKkjQOCeIFvDiF2VgA48Adm/usPyrWwa/NXBMkmHnmwctgyHUBe4INr6T1BBRh61v3CuYdrhlv7ydxvhsD8Rai7o6svqiplxRRRVjnCiiigCg0Vzneyk/14UAtZvNqmPgBt/XwpD4/x5GGc9GZEX5lj+Sn50444FnYdT+gArMvapPYQx/idj8Aqj/Maqj0H6cbKfJeJooYWR0OsvqD6UdRdVRWZG3Yx99lS4Us+/IU98A4hFixmNULEksr6AxCqqR7qCeQGpzfoLVmeZYLFJg4llw5jhDs6yNFpZi4GzPztbkDb47U/wCHzQ4DJMO4RHJWPuvyJlJc3HoTQ5I/cp43AA1YnC362kdySd2Pcj6kk/GukYQsD26ki9imHxDc7XsbDw/KokXtLxkrBIIYtR5LGjE/5qmnE5024RV+EQ/Ums/Kj2Z+TjfNFjBDf7WJb9nBv+rtV/w9GIJGlTDY2ZyukF0hQKCQWsC496y3J6KB41nbZ/mwxC4dnZJHvpFowCBc7Na32TV9h8qzpv8AeCvpKB/lFSoRi+EQsUE7SLJ+EHJJ+i49iSxJfE4RbliWYmwO5JJv515PBcv/AHKf/mx8Y/yx1DPBGaykg4+zAAkdvMSAbgGwHI2PyNZ3xJFjsNMYsRJOrDxkchhy1Kb7iraRfsVeOF/SjTJOCZf+5Mf2se37oqgTcDSXv9DQeuOl/dH5UucJ+zfGY6HtnxDQRn3C5di43uwGoWX8R59Nt6Vp8vj+nDDjF64jIqHEWbTvYFgpbdQet9wL8qaRJ0ivZGjtwdIP93hFvHGzn9FrxNw2y84MH8cTiT/ClD2g+zuTLRE3amaOS6ltJXS430kXPMbg+R8Kj8I8CvjsPiJASGjAEQ2s8nvFT8LD1cVOqLJL4G5+H994svHrLiD+rV7iyteRXLR6mY/q9ZhlGVNPiY4BcM7BTce794keQBPwprxHs+RMwgwyu0gZe0luACqAnbbqbW+IqNUSq9kPWUx/R31xT5XE1iNSo17G1xcyg2Nh8qmzQwszPJjco1MSWY4aJiSeZJabc+dZJxRw2MFjOzcMYWs6EWuYydwCdtS7rv4A9aeF9k2GxeBE+XYhnc8hKVsSB3kNgCj38dvgQamkC9dsKOeZZYv7ODw373NeBjsGP/e2CH7OCw38DWecIezufG4toXVoUha07MLFPwgHm5tsPjy5z/ahw9l2A0wYbtGxJszXk1LGnQMLe82xA6DfqKmiLNByfiLBxzof9KwyXOnQuGhTXq2A1xoGG5B59KVPbJLPgsf2uHkaIYuIa9O13jvESD0bQy94WPfbxrJlYjcfCtv9sjCfLMDirBu/Exve1po9ZBtva6AbUBnOBYQY/Dv9IXEGZUaR1LGzS3DK5bcspIJNb5wFj7SNGT76g/Ef1+dY3xVw5BFhBiII1VgyESJJIiEE8o4cSTK+/UWtzIrQ+G8aQ8bqfP8ALVVJPmzox8wcTXaK+K1xevtaHMFFFFAFRcfJZPiKlVBzX3QPOoZaPYr4+b0vdgLdTfess9pUbfSMMo3ZlNh+IuAB8wK1lsOSSRsd7el6yX2sAjEYcm47ji48nB2/vVU7cj/0z1xGBozF45I3kaSL6Sq9taPv94RtJs4M4G/MDYbb1d+0PBGPKMIPs3w//wBpiKo+NM2eWOeFIsRLHHJ/rLMCj6W0iRuyhVW1A7Fma2rnemn2gnteHcJIOgwbfOMofzarI474Fr2TRDtsQeoRPkWOr9Fq0my7NyxPaxILmwBW1un2SbetUXsuyRsTiJRHiGw8qxaoyoB1d4Bgynmo7pt536U+S8EY/nJmRFvuoB+8VBZNUkJ8+OxDZvglxUSxlCwXTchtQYFgfUDbpTDn+Q4qedWgxbQR6FBUF/eBa57u24I+VQuMcyhGYYBNaloptUjAiyBiosW5DkT5WqTnuAy/FSK8+LVSqhbJOqjmTuB1350J9hUz8YrLMXE/0ppZTHcMdR7oYgoQxN1vvbz8d60TK8TDnGDR8Vhh3X2BGxZbEmNr30nkRy5g3rP8zyDLBioBHi0EGhmmJkLsSGUKikDYsL+gBPO1S+OvaKnZLhcvbSmlQ0iXWyjkiciPNvh41JTom+2HP8TFEsESGOCQWeRbWb/hC3uiw3HUbDa98YYVrGQ+1KKWBoMyXWCLa9OoOPB1HJvxD8jvWecRw4YTE4N3eI7gOpBU/dufeHnUoqzWOFscuc5LJhJjeeJQlzzuu8Enj00n0b71TMqEWU4DDRzkKXZFfl/ayd5r+S8ifBRWRcFcUtgMWkwuUIKyKPtIedvMEBh5r51P9o/HC5hLH2QZYo1Ng9gS7e8SAT0CgelRXsLNHXgxY8zfGKBpeM93wlYgOfQrc+rGuXCOD7ZsXjipYyMyRAbkxRd0afNivLxWlHL/AGq6cvMEgdpxG0aOLWtbShYk3uAfjpHjXTEe1MR4OLD4FXiaMIutwh7qg3sLncne586ii1obuKeHXzHLEYxGLFRqXVDz1DaRPRgLjz0+dJfsdnxYxwGGP1W30gPfRo33P4+YW29/K9fMh9reJil

JxN54yuygKpVuYIsPUEVY4b2sxQJKMJgmR5Gd7ki3aNvdgBcgeHgLbVJBseYYhmjnTDPGJwuxbcK7D6syAb8htfoBzAtX5lxGFkixzrjQRKDIW7Xe8hDFGY7gqWsb7i3lXXJuK8Zh8YcUpdpHN5NQNpAdyGA6eFuW1rWq/wCOON48yiF8DIkyW0Shr2F91YaO8vOw6HfxvJAv8UyQM14du93QSpbRpW+soSL69Vt72v001pvFo1cJ4cn7KYT8rp++sZXLpTyjc/8AK38K2bjf6rhfDIdiVwakHx0mQ/pQgpuIcphbCy4lop2doGKs8GINtQwxj+sYFVCaJd72tKLVf8IOTFAfwRn/AA/ypNzeFFw0+EWFNeCQO5WaYWeQwxzMFdbOFYICCQO8StxTpwrHpiw4/wCFEf8AAP41SR04fc2TL3vEh/Cv6VIqFkzXgjP4RU2ro5mFFFFAFQcyW+n41OqFmLbD41D6LR7F6VRq3+958jv09DWc+2HL1ZYHUbBpEP8AzBSP8hrSMU+5Bvp628tx+ppe47wCSYCSwOpNMlv2fe/wlqhHZJXATHzh8XDOyRz6mhEcrSzj6NEAE1dmrAAM3ZjSpOxbYGnLhrBLj+HhAziPSChdhcJ2Th1JFxsF0/CqDgvNWbClAkj9izWNsMY4w29wJWUliSe82octqufZfiTBisXgZVKm4lVX03tYBgdJK3KNGdtudEcgvQcD4BDc5ql/+Etz81Y1LXg/LTzxWMm/YhkP6RGrbMOIcZFNLH2qpokZbJFGNr6kO4PNGQ/GqvMOMMQikyYyQbEgDs1Jt0ACgn+dZvLFOjmfiIRevJ6HAuXdMPmcnpEwH5qtexwNghyyrHt+26r+soqtwXEr4hQfpU5Nl1DtZBYnpcEC96k5fnEmGnWZWkkA2kRnd9cZ96wYnviwZfNbdar50bplf6qG2rTRJ/6EwX7uTS2/HPH/APtNejwpGOWTwjzfEx/zqJxbkUaP9KjPa4bEEOrgkhHffSbnZGO6+BJXbu3Ss3dYV0hUYkEhiF1KS23dtYra6g+I3qzyVLWi0s9S1oeZMlVN/wDR2XL+1iEP/wCOuB0r/u+UJ6yqf0SlGaMLg3kCrqCsytoX3b924ta+m16ppsaxDE6Y7ShfsgAFGYDVpO11uPWojPb2Ij4hyul+/wDBoyY4DrkyfEn9BXyXNt7fScoHpG5/fSJBJIJYo9RYSFZA4tugUllvYX7wHSoMeLlaA952fVFe5bldgRfSLA3F7E02Hnv4/f8AgfJM83/1vLPhDJ/GuJz0g7YvAD0gk/8AVSrgNRw5DFtYDAkg3B35X526GqrA5lYaTqCbljzIBFgAenU3+VQpt3S6Ec8ndLo0F+Kntf6bgxbww0n/AKqlZnmWIw5Xtsbh4ywuoGGY3A5mwY+Nqq+HsqWVjLKdOFw/edm5My7hfMLYFvOy9TUHNMyOImeVgRrPdB5qgvpU+e5Y+bGjyVHZol53GGzX/Bbnil//ABKP4YN/414HFTf+Ij4YNqUMdjyFcpa6EXDDne1rfOueSzuykOB3SRc31X57j41HmPW6Hnyrah1Tip7j/wBpEcgLYM9dhz87V39qU7S/QsJquZZgSSL2taO5Hh32PzqiyXCdrioU6Bu0b9mOzfm2gf8ANXDizFmbNL9mZ0wwjRkDEEsxtZSN9WuTYD7nhetMctlZtjm5wtkfijNsRJh+zbWqsyIOzdHhlA9zvAlxawIQsw2202FaXlyEaFYAFECf3bDf9Ky+CCGTH4JYEQJeORiqsrGxu2pWY2to2sSN73N61d5frpG8vzq0jpxqk2aTkg/7NF+wv5i9TqjZammGMeCIPyFSaucwUUUUAVCzVe5fwP8AKptc8RHqQjxFQyU6YtYkXAPz9Kh45EZCttiCD5g/yNT3IDafKoOkBtJ5HlVEd0DFMsxxy/HSxu4jIDx9qUMhVdmVkjuAzMFW2rYFr9L0wYnENhDhMfHDOnYORKcQUEs8UjG0rIO8NReWO5B/2feNdfavwu40YuIbrZXI6C/1bfA7fFa+5JiY8ak0k5ffeVC3ZQRiaSFZvrjuzsU7dYtkBva+97HLJauhw46wayJFjoTqjdUVyOqtvDJ6XYof21+7SXmeFWSFlYhRbdjbugEEkX5GwNXPsr4jTTJls7CSMmUQMw2dDq1JY8tQu4H4mHQVE4iwDYSUwsSykExuftpy3/EtwreOx+1XNmhzujzPFYqfmRE6eFDEwjPZwB9faSXuWtpsg5keZ+FWOU5qXRQ+z2uL7FlFhr08wP4Xqk4mguCxJYHZd7JEotckDmTyFVeBR5HGhnXa4kI3YrsNR6KOQX0veo1U4XZXRZIXZpuSZ/8ARtccidthZb9pFa+nV7zIvUH7SdTuN76ouecHrpM2GYz4Z1sGjbU6LzFx9sKTcH3l6g86pHxgBVGYaiP69L9BUnA4+SB9cLlCTuOat+0vj+IWPnVYzpayJhLjXJ+GdMRiwY2ZR2gA90W38RbyHSlqPGNGtiGctqP1in3VuNYA3UtcLbkCvgaeRm2FnN8TA0Uh5ywXIPmbb/3lPrXaDh6JzeDGwsbW+tADAeFwQfyq0YV1yWWCk9aYlyAFl2mVfqkdhJbS7BQAV6kBgCRb3q4JmC3jvddUciqWYmxWQrbfmeW/PpT7J7OnZxJ2uFuCDfXJa45EraxI6GoWJ4JwkYAxGOw62JIWJQzXO5tqZjufw1OjfaK+TJ9r9xDy2cqZFdr6bXck21XIIGoC3oPCmXLOEu0UzYi2Hww7zO+zP4aQd1FhbUd/ujrU9cbhYDfC4Z55BylxJIA8wDv/AHVX1qDjZpcQwbEOXIN1Xki/sp4+ZufOqylCDt9kyljxvZu38I95vm/bhIoU7LCxW0JaxYjkzDoAdwp6m535LmdYzs1spGs9PLqbVYZzi2ijBUAFmC6mvpW99zaqLERo7sUYylhd1ta5XmYWI5r4eHjVY3N7S6MoSeSW8+iKMEVdNLsyuB7nPa3K/O3zApjw2E0i1yx6k8z6n414ybI1ULI1y25UkEbEbXXlqsd6Zch4fOMnEI2jFmnYfZj+6D997FR4DUegqJyeSSjEiWR5JqETvw4qYXBT4+UDvL9UD1RSQlv/AJkhv6BTSJAuLw8YxSgSCb6yUFNQXdtDPbvIWDMwbbZhv4OftHz6PFY2DLodHYwsplAdUDuu3ZIxIUFVug3Hea19hVFxYyRpMoaFZ+1VMOMMrxSiEhw8c8dhYAdmoDXa992G9d0Y0qPUXCSR04D+vxEmKZQgREijUXIUAKLC9zsqj4uaf4Vvb8R/l+pNLfDGWdjDHEBuN282PP8Ah6Cm7IYe1xUajlrH91N/zsfnWb5OxrSNM1FBYW8K9UUVscYUUUUAUUUUBR42ICQj1I/WqfFj57EUyZrBcAjxtS3jlA0gHe3LxFZvhnXidkSbCI6MpJZXBVlPUEbg1lWPyL6HjEhxJYYdnR7r9qK9iwH3lBYHa438a1KVyp2/r0pe4oyr6ZHpZu8vuMfsn+B6ipNMmPdWhf4ljUYNHieFPo6wlZ4yLGZRIHijZRqlkciGW5uEubkcqv8AJuII84wjQYj6vFw7ttZlcXAkRT06Mh8SDsRWeYHPnwcqYbFoiGB5GSVkLvDrAZjEt9DFiqlWYHSWvVtnmWEyRz4T6jEKI5N2YMI5FBQYl5DpbEO5Kjfvh7kAWqzRxd8M443AvHI0E6jUB/ysvRkvzU/MHnvX3C4FcPCxRSbb28ztf0H7qZMlzyDNE7DEr2OJS+3IhhsTGT6bofzG9esbk74fuyWK9JFHdPqPsnyO3ma5JY3Hrr4OWWDXldCHigLHvhgbO5tvq+yoP9da+w5i6oC1n1arACxBG7XJ6CrvNcoVlsvctuLcr+Yqlx+GkJ0aS26lHuBpO2on4gmrbRlwRcXwyThc2QkWax22O3MA/HnV7g50bZtN/O376V8PEHnlcgEKVVfUcyK8Kb4mRyoZUAFyeRAJG3Xeqaq+DPRXwO0uXRWJKJ6kCoLKiEAaVvyAsL+gqPNDZQLagwgYgnmxLfryrxh8qSXDKri9i1iL3Q6jYA8xbaqZIUrbOfNipW2cJs/gViC+4JBsDYHkbm3Lcb+dU+Y5nJKiaQVV9QIU97WhuU1D7yja3Wo2GXsowxQuF7eGYLzuSCG/QfCpGByWQLEdelSUkdSNw68reFxa9XUIY+Syhjx8/wCQyzNAiEOkhiZiY2Ya+6eQPxFWEGU2lEjOzadRRTsF1eQ/TyqVhsMsYIXYElrdLnc28B5VaZDkk2Nb6kaYwbNOw7g8Qg/2jeQ2HU9Kytzl6DG5ZJNY13/78HHAYOSeUQwqGkIvv7qL1dyOSjw5sdh5MHFXECZThlwOCOvGTEXc21BnsvaP0DHYKvJQB0Avw4k4zw2TwthcEBJiT77tZrNa2qVvtP4INh5DYo/CuKE3al1ilxryCQnGe7LDbvqkjEdm4N31bEhe6QVs3ZixLGvuejgwLEvudcF2uWrO8cseKiDrFi411qyPdgpDsA1rhwJFuL7MNwK85J2mNxJxU7O6x9yLtCC2kX0gkAA6QeYHM+VfM1zCTH4qeCFlOG7Us0ojVXlVSwiaVwAXaxNibXJud6ccmyxUVQBZE2H9f1zq8nR6GGH6n0Too9CFj7x2HkT/AAFN3s7y3d5iNh3F9ebfIWHzpaWJpZFjQXZjYDzP7hzPkK1TK8vWCFI15KLX8TzJ+JuarFW7JyzJdFFFanMFFFFAFFFFAeZEuCDSvmmXEMNtwSV8LbXHxpqrhi8KHW3Xoaq1ZeE9WIc/l4/KomLiKrdRsevgRV9j4dPaXG99v6+NQUYWseXI1Q74y4sSeJuG1x8AVu7Ol+ykt05lH8V6jwN/G1ZficwxWGvh5GZQNd0IBDawFJN9nFlWxN7WFrVu2Ky3Rex66gaXeI+Ho8WmmVdLrcK67H4fw5VZMpkxKfqj2KGQcNCTDxSam7Z+2lUrdnYArHEoF9ryA3Y/eXzs6ZfxdJEujFr2qXKdqveBt7wv7r+o/OkTD5biMAzA3aF9IcqSA6g30sR3lvc/PrTXhc3jxDYZXKRhH1OhBKm5jjRETwIvcchdjUs5argtMRkkM668JIBzuvNflzT+tqXMxy+aI/WxMF+8veX1uOXxtVNjZjHPpw4dCp0CzEsWB072tuT0G1TMB7RcWrdm6Cc7i2kh7jmO7zOx6Vm8akZSxwn2ckZDfRbc72t6dK7Zfli3fn3yS3x2qYnG+XzkfSMOVPjpDfJl71X2TrlEhGmcx+WuVf8AMDWfktdMwfh3+lkfBZABHZmYnUhvtfu+6PTc1Hx+UWl7RXZVLamQcif508iDKgP9bP8A9U/uFQMzzHJIlu7GXyvO9/hcCjxTfbMpYMj7Yg4mdE5lVJ6bXJ9OZNScBw/ip7GKBwp+3L9Wnr3u8R6Kasx7U8FG2jLsveRzy0RohP8AcDOapX9omY40S6HhwMUbIjsQ5YO5YIl7M5Y6W91RbSaR8Ml2yI+CgvqdlziOG8LggJMynV+ojFwh8gnvyfHbyquzT2hYnHKY8vQ4bDI0aST2F0VzpU2X+zXn7u9hzFVDcFrLBqlkkkxcizBTJIATiIm3hEbLqa8dn1My/wBolhc2MjPOL8LDK7YcXkkjQOIlVYnR0DoNibSwkgatPeGpWHMnojFR4R2Rioqkj7LwfhkiaCU6WQFpcToHMmRopO0eQfVMgVezVS2oODvalCJcTmLxh2LLDGkQYgAJGt9K7AXO586vosixGPcT409nH3iqKLGzMXIRT7qlmY79SabMuyhVUKihEHIfz8aOVHTjw3zLo85FlKQxCOMbc2PUn18atJpbbD0AHjXREC7VfcL5GMTJrK/Vodz94/dHl4/LrWXfCNpySRacB5AUBxEo7zbRjwTqfVv0A8aca+KK+1slRxN27CiiipICiiigCiiigCiiigIWZZeJF/F+vlSvLhOY8zcHnfpTrVVnOUdoNS7OPz/nVJRs2xzrgVRHsQelv1vUWfDhxYnf95NTXBW9/QjwriEAa/IGszrTKabC6feFx+RHmKo8ZwbG5vE4iY725r8unw+VObrub8h8jUOXBK247p8qtYdSXqMvzDIMZhn1hSdJuJIu9a24PiPiKo8BnRineZtRl0ylT1ErAgMb+Gpj62rZhBIvKxqrzHLIpf7aFW8yov8AMb1ZSMXg/wBrFfDZph3EghKL/YhFdo0OkmaaW3bKyn6yULba4TnXrDzJ/o+EiOHtZHn1MEUOFTstG68rsX3PMVLn4HwpOwdP2WP6MDXaPhGAADt3Xc81U9Da9rUso8My+xmCwixPKqodMfbqpN7rMrxxJa/2JADbz3pV41kWWCEosCAQLI4QIp1l2jYc9ROynR0FzQch3sHJF+ZX+dcMw4XUue+7JewNgL+dul6bDyJkD/ptpTCo817xYkTEx6gjO2lF7NSgICwwna477bG5FUy8SKmJxIwsAbDzOrCFtYIKHVGymNgyMCWtZtgxG9M2F4MhtugLb21G+w8uVXOE4dCiwAUeAA/dUbfBdeGf6mJmJwmNxzFsQ4jRmDaRsAQojBCDqEVVuTchRcmr/IeFIoiCi63H236enQfrTJFlKLz39a7k2AsLCobvs1jjhHo5pCARfvN+Q+Fe2l3tyry2KWPc7ncWH8a9ZFlMuNl0R3WMf2j9FHgPFj0Hx5VTsSlXJY8PZO2Kk0gWjW3aP4eQ/Efy5+FadhMIsSKiAKqiwA6VyyvK48PEscS6VX5k9ST1J8al1tGNHFOezCiiirFAooooAooooAooooAooooAooooCszXJxJcrs36+tK0+HKnSQVYeNPlcMVgkkFnUH9R6GquNmsMjjwIay9OR5VweEA+Hz/jyq8zfhKS5aBg34W2PwPI/G1UGZQOo76lWtyIrN8HVGUZdM4aBe5fQfW4NdZgQALg3uar4YC3kPGpOOxIVdI9P51FmrXsfWQbbA/0TXLsb/ZqAspHI2qxw8mpbnnQNanB4wBax8LV57ICwtbxva1ecTmRvYW28ahSYsnr8qEpNlhJAL32G1vGvmkeJ+FVk0zLbfnUpcdyHU8h50KtNErWOWm/nVdmOahe6tifyHr/AAq5i4Xxs4AjQRg83lOmw8l94n4WpgyL2VYeI6p2OIfwPdT+6Dc/En0qVFmTyRXYl8McMzY57glYge9IRt6IOrfp1rYMryqPDxLFEulV+ZPUk9SfGpMMKooVQFUbAAWAHkBtXutEqOWeRzYUUUVYzCiiigCiiigCiiigCiiigCiiigCiiigCiiigCuc2HVxZlDDwIuPzrpRQFJi+EoWuV1Rn8JuPkaoJfZ49zaZW/aUg/kTT1RVdUaRyyj0zNZ/Z/ir7GH4M371rqeDMUEsFS/7f8q0WimiL+fIy4cAYtjusa/8Amfyr7B7L8QT3pYlHkWP7hWoUVGiHnzEvB+zKIG80jyHwWyD95/OmbL8jhgH1Uap5gb/Fjv8AnU6irJJGbnJ9s+Wr7RRUlAooooAooooAooooAooooAooooAooooAooooAooooAooooAooooAooooAooooAooooAooooAooooAooooAooooAooooAooooAooooD//2Q==

It might really make a difference 😉

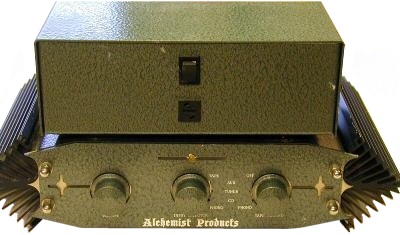

data:image/jpeg;base64,/9j/4AAQSkZJRgABAQAAAQABAAD/2wCEAAkGBhQSEBQUEhQWFBUWGBUaGBgVGRgdHBoZHB8XFxcdGhgYHiYfHh0jHhcXHzAgIyopLC8sFR41NTAqNSYrLSkBCQoKDgwOGg8PGiwlHyQqLy4sLywsLCwsLCwsLCwsLCwsLCwpLCwsLCwsLCwsLCwsLCwsLCwsLCwsLCwsLCwsLP/AABEIAOEA4QMBIgACEQEDEQH/xAAcAAACAwEBAQEAAAAAAAAAAAAABgQFBwMCAQj/xABOEAACAQIEAwUEBwUEBgcJAAABAgMAEQQFEiEGMUETIlFhcQcygZEUI0JSYqGxcsHR4fAzkqKyFTRDRGOCFhckVFWD0iVFU3OTs8PT8f/EABkBAQADAQEAAAAAAAAAAAAAAAABAgMEBf/EAC4RAAICAgIABQMDAwUAAAAAAAABAhEDEiExBBMiQVEyYYFCoeEUkbEjUnHB8P/aAAwDAQACEQMRAD8A3GiiigCiiigCiiigCiiigCiiigCivEkyqLsQPU2/WoM2fwr9u5/CCfz5UJUW+ixoqik4rQckY+th++vB4sH/AMM/3h/Cosv5U/gYKKX/APpao95CPiDXeLiqE89QPpS0Q8cl7FzRUCLPIG5SL8dv1qarg8t6kq012eqKKKEBRRRQBRRRQBRRRQBRRRQBRRRQBRRRQBRRRQBRRRQBRUfF41Yxdvl1pexudNIdN9A8uvqaGkMbn0XOMzlU5Xc+XL51RYniGRuoUeC/x51VYnMOwBYsAg3JYgAfE0k597VY79nhYjNISAG303OwAUd57+G1Vs6Vjhj+oeMVibsDcm/jvVPj+JIIS3aTRofAsL/Ib1nz4TNMY7pKzQBFLtG14yIwrvrEY77r3CtxfvMoPOl3IctinhxRYv28cXbRqNIVkQqZ7nmW0FiNrdwnypRD8QlxFGj4r2l4RbWZ3I+6h/VrVXy+1mG+0Up+KD95rxHhcHBPGzx4OJGhLyK8glBOrUkKli7I5R0V5dI9x9AuN6DP8VHJgcLFGyTSIQWEcTqVGnRoRuzAK90MzEks73sLbqRm88y+HtaiJ3hkt4XU1Ih9qWFZu92iX8VBH+EmlnKsbHHi8TJFDLgkkhZIGZZJDBIez72rTq3CyLqUEr2m3Kp+Gx+Af6V9InWSfELIglkgCBRHD9W/PuPJNpOoAkiPvaS5qaHnzHDAcX4aWwSdCT0J0n5NberzCZqybo5XzB2+XI1n2H4VwGIjijj06lbBRSSxkggmNp8VIzF2R1CRyjZQVYDmOcfDcNyhgcvxWxMS9m0iyKskjS90yR/VkLFEZmNtl2IvUUXWdP6kbTgOMjylXUPvLsfiDt8rUw4LMo5RdGB8R1HqDvX57w/GWJh/1yBtALDtIxt3XaIk9La0deYvpNqbso4jjmAaGQEjwNmX1HMUtrseXCf0s2CilLKOLCCFm7w++OY/aHX1pqhmDAFSCD1FSmc8oOPZ7oooqSgUUUUAUUUUAUUUUAUUUUAUUUUAVBzPMhEvix5D958q95jjxElzueQHiaVZ8RqJZjdj/Vqhs3xYt+X0eZ8cS5LG9KPF/HUOF7vvy9IweXgXP2R+Z8OtUvHftA0OcPgzqlJ0s676WO2lPvPfby8zyocm4SdI5Z8TGjykWRMUZEVZdffScsUIdkBKMW0MbjVqFqivk2nlUeIFJmOcYvMJD78mkMwjjUlVVdydI6Dqx+dOWUy4KDCQYyNUV4wsilmGszx92SBu/qbtdd1ZUCooQ7m9U2RcFzy4ho8BI2sALNPG2mBFdFMsetSS5DFl7pIYL8a0HLuH8uya1x9KxlgRcAsPAgHuwr5nvHpflUtpHI5e8mU/D/DeNliiTBRyYWJRiNM+Mb61RMYiwhWMBgAItmNrmRjteps/AWWQSs+PxJxE7Es6JZbsef1MA1D4kCo+f8bTS/20wgjPKONitx+J9nf4aR5VX4YKF7lrHcabWPntz9a5Z+IS6VnFk8XGP0qxhgz7AYfbC5au3JnWNPzbW/zrsfaNiPsYeBB5vIf8qrS21L2e5KZZdbSmONU3sTzBNzbkBYjes455Sfdfg514qc3y6/BoX/WTihzjw5+Mo/PUaJOPdYtPgYZB1s4P5SR/vrF8nyrt5yFLdkpuWOxt0Hqfypg4izeVZY4YDZ33J26kgDf0JrRyyKWqlf4NpTyqSipX+B3mw+S4j+1wz4NjfvorKBfY96EslvUCvH/VrKsD/wCiscksTdr3JNJsZFWNyJY7gMVXTuBYFuVzSFPm2Lw1jMqSJe2pdj+X7xTJgMQCFmjLRswDB0JVtxfcrz9DcU89x5kuPsT/AFMo05q18o+5xnOLhxU7TRHBYjE9hBEWscPFDq1zPrN1cl9yCDYSSV5zXhWMzN9ED4YwJrknYSgaACoZkRWDGVxqVoSV0arqNFNOC40fQYsbEuLhYWJ0rrt+JD3H+Gk+pqNNwXbRi8klEixuJPosjNpEqqyra5DKy6z9W9uZ3sbHeE4z6OqGSM+YsX8HxdJh5mw2OASRG09ovuE2BFyNtwVNx0YXArQ8kzxoTdTcHcrfYjxHn51nTthMRHKcT2w+hxSMcNIWRlZroZJJLXlxEkxiv7oAdfeCWpX4V4xbDkJKS0X5p5r5eXy87NfB1wyp+mZ+q8vzFJkDIbjqOoPgalVlvD+eFSJYmBUgE791lrSMuzBJow6G4P5HwNE7M8mPR/YlUUUVYyCiiigCiiigCiiigCvEsgUEk2AFzXuqTPcVdhEDYbFv3D99C8I7OitxmOEjFnvbko8B/Gs59o/GfYoYMObSuO+w5xofD8TfkN+ZFOHEOdx4WB5D3yB3RyDMfdHz/IGss4eytp52xM0RxChizxkN9dcN2nZn3WdLqwjvc2AF7GqnVklqtUQMHwdi8NHDi44VnBEvaRsquqqByazHZo2J1CzKVbkVvTbw/lk+ctq1TwYGwWQs7F8R7p7MkHTIEIt2xUMRbVqYbecFwzFjMS2DwihML9RNiZUYlWst07JX1NE5LulixNgb+7amTi/OVRPoWFAjijGiTRsLAf2SnoAPfPPfTe5e0Skoq2cU5qC2ZzzfipIYxhctVY407plQCw6ERX2ZvGQ335XO4Q48wErSxQvaRd2dgWuSSGO5uxvzY359alRY6I+7Ih9GWkbHa48bIYb6gzMNO+1tR9RYnauVXlbvj4POUpZ5O+Pj+TnmAZHkScM0lxZyx2F73t1BHLwph4Xz+JYVidtJBaxb3bEkgA9OfWvJg/0hErhTFIhA1Ed0jqAeZtz8j61Zy8OwaAZQCQO8+yX8zpsKmeSLjrLsnJkg46T7+x3xU8jNH2JjK6vrLkE6duVvj+VV3FuDnkRUiF1Ny4BANx7vPpz+Iq94f4NkO+Fwz2b/AGjnQpHk0neI690EVbz8KtH/AG+LwkHkWLH/ABFKzjCSdxX9zKGLIpJxj188f9mYYTC46JCkaaQSTtovf1veu+bs8OKinZSyhEBI8QpVrnxub07y5VFyTMcIx8CLfmJTXLE8M4i10MM6/wDCff5MLfnWr3u2kdGmW7cV+BFz7O1xKpFEDuwJuLb8gPzJrnhIHxkugPpijUAeSjujbxNr3phnw/ZNaSIxN01qBe/g3unl0NUH0CWCRmiXWjAgr5HmCOfxFIySWqVP7kxqK1Sp+1k2JZcJpkjkE0BIDWNwBffbe3qPjTphsTJDL2sLmOQbXG4YfdkXky+R3HQg1n2XYR1LyMTh4rgEMCwa5sF0n3vjXeXNMVJiZFjfSVLWS4F9JtYA8z1+dRKDbtPle5nPHJyuLVr3NSzbJsPnkRuBhswjXn0dRyN+bxXtv7yEi/4kFclmleZMfHLLJgIoo0w8IVXZCWs2pVN4lG5cBida773qZw5nTTLqBMc8LA6l2KtvZgD6EFTsdwdjTxmeWrnOG1qEjzDC2I5aXG5AIbnDJY2vfS2oHrfbHkbesu0dOLLs3GXaM6yriOPCYgxRyNJg20FWbfs2dVZlJsAdJLKbAX03tzrWeFs77CUXP1b2B8vA1ludZxiMwiiwkadn2fexWu0aLLEj3ug7saKiu2wGpi+2wAncJ5hJFI2BxFu0jA0G9wVsGFj1Gkgj8J8qu0ejilstGfo9WvX2lvgnNu1h0Me9Ht6r9n5cvlTJV0c8o6ugooooVCiiigCiiigPE0oVSx5AEmk+eTWST7zb+lXvEE9kVPvHf0G/62pWznMhFEzHYBSbeQFzc+NVZ2eHjxZn3H+ZdtiFgQgJGRck2GttiSfBVI9LtXTD5rPgoXhbCsmk6O0jeZPrfsuDcoWNge7YMOYNROF4u2xLsZRFNsyMXVTrd1VmGrY6EaRrDc2FqZ8mw0uIx+FixLM/0ZHnftL6gC7fR0kFypYd1787ORuBSzCT2dl9hMIcsy0Lf/tc7Fnbme1canY+IjW/kSB96kjHZaskZQ6gpFjYm9r3N25m/Mnrc350x8V5t2uKcA3WK8a+osZT8Xsv/kis2z4zPMQFdRLYBb+8RYcgbeBrmn65ap9HnZryz1TqiqzvhPsh2kf1kXM25geNxzHn+VTMgyGImOeJ37re6wHPkRcevMU34OImFQyaCFClTY8gBtbmNq84fLz9XDAg1MQkachfc3PgoF2J8AetZPLJrVdnPLLNrRdnnA4GSWQQwJqci9uSovLU5+yt9vEnYA71cyNhcA1goxuMXmzbRQt4AbhSPAan8St665vjFwUZweEY9obHEzjZyxHuqR7rWty9xSoHeNwnZhqSB+xHeCnSAPnYdTa59anjHwvq/wAE3HB6Y8y+fg7cRcW4mSRFmlJV73VW7KMAEAgAG7Gxv3mOwpbx2aKv9iikb3kt3b7m1x7x28bedecXij3gheZCYR9YATrJYMF1ra5AHTY1wmxspSIKQWaOS4UD3lI2t0IHTxq+rdORdRbacufye455SrPoAuFNzcqR00oeWx3v4V8bFvZSsZR7++isNS72IK2IubbHpXXCh2dLB9CvzbUCQVa+rVzsbfOuWHws8atfUbxAL1sxYA8uoBJv4elT/Y0VL4sZ8Fns6oBJadGA1RzWJF+YD2/zBqn4bIIsQCcASsii74aU2NvFGJNh53Kea0oYHHMkkaSE7oQL33cOw5+YH6VfwyaWV0JR1N0ddmU+IP6g7EbEEVRyadT5RSWZr05OUR84y3toniIKOp91wQVcdGHTY/mCL0q4nCYlnjBiIlUj60X3AtpLMNja3PnWulRmcJZQq4+BRqC7CePe1vU3tf3HNr6W3WVkBF/12PhYg8jfa3SobeL6eUZyk8HXKfRBkkiwgZ2O8sl2PW7E9PuqLn/+1b4HMnglSeHd0vtfaRDbXGT4MALHoQp6Un5zkAmnLKyoum5JN9TG/IX26XqzyCNYYQjFFYE3IYWbwPyIHwqkqSUk+TF0kpxl6h14ziWKSDNcM7Lhp9H0koqkg2YQy2IJVgWKMR3huObGk3iTLSqRzwMrzYZVlnkZl7VxJ2QDOgFwNbsR2hEhWUXFhTxwJi4sTHisulKtHKjOoBBsGIWYC3KzFJB5s3hSNHLKiy4fFrPizBKYDEXCQBtLLG7aLySMFjdwQLqEBuRXoRltFM9fHPaKkjQOCeIFvDiF2VgA48Adm/usPyrWwa/NXBMkmHnmwctgyHUBe4INr6T1BBRh61v3CuYdrhlv7ydxvhsD8Rai7o6svqiplxRRRVjnCiiigCg0Vzneyk/14UAtZvNqmPgBt/XwpD4/x5GGc9GZEX5lj+Sn50444FnYdT+gArMvapPYQx/idj8Aqj/Maqj0H6cbKfJeJooYWR0OsvqD6UdRdVRWZG3Yx99lS4Us+/IU98A4hFixmNULEksr6AxCqqR7qCeQGpzfoLVmeZYLFJg4llw5jhDs6yNFpZi4GzPztbkDb47U/wCHzQ4DJMO4RHJWPuvyJlJc3HoTQ5I/cp43AA1YnC362kdySd2Pcj6kk/GukYQsD26ki9imHxDc7XsbDw/KokXtLxkrBIIYtR5LGjE/5qmnE5024RV+EQ/Ums/Kj2Z+TjfNFjBDf7WJb9nBv+rtV/w9GIJGlTDY2ZyukF0hQKCQWsC496y3J6KB41nbZ/mwxC4dnZJHvpFowCBc7Na32TV9h8qzpv8AeCvpKB/lFSoRi+EQsUE7SLJ+EHJJ+i49iSxJfE4RbliWYmwO5JJv515PBcv/AHKf/mx8Y/yx1DPBGaykg4+zAAkdvMSAbgGwHI2PyNZ3xJFjsNMYsRJOrDxkchhy1Kb7iraRfsVeOF/SjTJOCZf+5Mf2se37oqgTcDSXv9DQeuOl/dH5UucJ+zfGY6HtnxDQRn3C5di43uwGoWX8R59Nt6Vp8vj+nDDjF64jIqHEWbTvYFgpbdQet9wL8qaRJ0ivZGjtwdIP93hFvHGzn9FrxNw2y84MH8cTiT/ClD2g+zuTLRE3amaOS6ltJXS430kXPMbg+R8Kj8I8CvjsPiJASGjAEQ2s8nvFT8LD1cVOqLJL4G5+H994svHrLiD+rV7iyteRXLR6mY/q9ZhlGVNPiY4BcM7BTce794keQBPwprxHs+RMwgwyu0gZe0luACqAnbbqbW+IqNUSq9kPWUx/R31xT5XE1iNSo17G1xcyg2Nh8qmzQwszPJjco1MSWY4aJiSeZJabc+dZJxRw2MFjOzcMYWs6EWuYydwCdtS7rv4A9aeF9k2GxeBE+XYhnc8hKVsSB3kNgCj38dvgQamkC9dsKOeZZYv7ODw373NeBjsGP/e2CH7OCw38DWecIezufG4toXVoUha07MLFPwgHm5tsPjy5z/ahw9l2A0wYbtGxJszXk1LGnQMLe82xA6DfqKmiLNByfiLBxzof9KwyXOnQuGhTXq2A1xoGG5B59KVPbJLPgsf2uHkaIYuIa9O13jvESD0bQy94WPfbxrJlYjcfCtv9sjCfLMDirBu/Exve1po9ZBtva6AbUBnOBYQY/Dv9IXEGZUaR1LGzS3DK5bcspIJNb5wFj7SNGT76g/Ef1+dY3xVw5BFhBiII1VgyESJJIiEE8o4cSTK+/UWtzIrQ+G8aQ8bqfP8ALVVJPmzox8wcTXaK+K1xevtaHMFFFFAFRcfJZPiKlVBzX3QPOoZaPYr4+b0vdgLdTfess9pUbfSMMo3ZlNh+IuAB8wK1lsOSSRsd7el6yX2sAjEYcm47ji48nB2/vVU7cj/0z1xGBozF45I3kaSL6Sq9taPv94RtJs4M4G/MDYbb1d+0PBGPKMIPs3w//wBpiKo+NM2eWOeFIsRLHHJ/rLMCj6W0iRuyhVW1A7Fma2rnemn2gnteHcJIOgwbfOMofzarI474Fr2TRDtsQeoRPkWOr9Fq0my7NyxPaxILmwBW1un2SbetUXsuyRsTiJRHiGw8qxaoyoB1d4Bgynmo7pt536U+S8EY/nJmRFvuoB+8VBZNUkJ8+OxDZvglxUSxlCwXTchtQYFgfUDbpTDn+Q4qedWgxbQR6FBUF/eBa57u24I+VQuMcyhGYYBNaloptUjAiyBiosW5DkT5WqTnuAy/FSK8+LVSqhbJOqjmTuB1350J9hUz8YrLMXE/0ppZTHcMdR7oYgoQxN1vvbz8d60TK8TDnGDR8Vhh3X2BGxZbEmNr30nkRy5g3rP8zyDLBioBHi0EGhmmJkLsSGUKikDYsL+gBPO1S+OvaKnZLhcvbSmlQ0iXWyjkiciPNvh41JTom+2HP8TFEsESGOCQWeRbWb/hC3uiw3HUbDa98YYVrGQ+1KKWBoMyXWCLa9OoOPB1HJvxD8jvWecRw4YTE4N3eI7gOpBU/dufeHnUoqzWOFscuc5LJhJjeeJQlzzuu8Enj00n0b71TMqEWU4DDRzkKXZFfl/ayd5r+S8ifBRWRcFcUtgMWkwuUIKyKPtIedvMEBh5r51P9o/HC5hLH2QZYo1Ng9gS7e8SAT0CgelRXsLNHXgxY8zfGKBpeM93wlYgOfQrc+rGuXCOD7ZsXjipYyMyRAbkxRd0afNivLxWlHL/AGq6cvMEgdpxG0aOLWtbShYk3uAfjpHjXTEe1MR4OLD4FXiaMIutwh7qg3sLncne586ii1obuKeHXzHLEYxGLFRqXVDz1DaRPRgLjz0+dJfsdnxYxwGGP1W30gPfRo33P4+YW29/K9fMh9reJil

JxN54yuygKpVuYIsPUEVY4b2sxQJKMJgmR5Gd7ki3aNvdgBcgeHgLbVJBseYYhmjnTDPGJwuxbcK7D6syAb8htfoBzAtX5lxGFkixzrjQRKDIW7Xe8hDFGY7gqWsb7i3lXXJuK8Zh8YcUpdpHN5NQNpAdyGA6eFuW1rWq/wCOON48yiF8DIkyW0Shr2F91YaO8vOw6HfxvJAv8UyQM14du93QSpbRpW+soSL69Vt72v001pvFo1cJ4cn7KYT8rp++sZXLpTyjc/8AK38K2bjf6rhfDIdiVwakHx0mQ/pQgpuIcphbCy4lop2doGKs8GINtQwxj+sYFVCaJd72tKLVf8IOTFAfwRn/AA/ypNzeFFw0+EWFNeCQO5WaYWeQwxzMFdbOFYICCQO8StxTpwrHpiw4/wCFEf8AAP41SR04fc2TL3vEh/Cv6VIqFkzXgjP4RU2ro5mFFFFAFQcyW+n41OqFmLbD41D6LR7F6VRq3+958jv09DWc+2HL1ZYHUbBpEP8AzBSP8hrSMU+5Bvp628tx+ppe47wCSYCSwOpNMlv2fe/wlqhHZJXATHzh8XDOyRz6mhEcrSzj6NEAE1dmrAAM3ZjSpOxbYGnLhrBLj+HhAziPSChdhcJ2Th1JFxsF0/CqDgvNWbClAkj9izWNsMY4w29wJWUliSe82octqufZfiTBisXgZVKm4lVX03tYBgdJK3KNGdtudEcgvQcD4BDc5ql/+Etz81Y1LXg/LTzxWMm/YhkP6RGrbMOIcZFNLH2qpokZbJFGNr6kO4PNGQ/GqvMOMMQikyYyQbEgDs1Jt0ACgn+dZvLFOjmfiIRevJ6HAuXdMPmcnpEwH5qtexwNghyyrHt+26r+soqtwXEr4hQfpU5Nl1DtZBYnpcEC96k5fnEmGnWZWkkA2kRnd9cZ96wYnviwZfNbdar50bplf6qG2rTRJ/6EwX7uTS2/HPH/APtNejwpGOWTwjzfEx/zqJxbkUaP9KjPa4bEEOrgkhHffSbnZGO6+BJXbu3Ss3dYV0hUYkEhiF1KS23dtYra6g+I3qzyVLWi0s9S1oeZMlVN/wDR2XL+1iEP/wCOuB0r/u+UJ6yqf0SlGaMLg3kCrqCsytoX3b924ta+m16ppsaxDE6Y7ShfsgAFGYDVpO11uPWojPb2Ij4hyul+/wDBoyY4DrkyfEn9BXyXNt7fScoHpG5/fSJBJIJYo9RYSFZA4tugUllvYX7wHSoMeLlaA952fVFe5bldgRfSLA3F7E02Hnv4/f8AgfJM83/1vLPhDJ/GuJz0g7YvAD0gk/8AVSrgNRw5DFtYDAkg3B35X526GqrA5lYaTqCbljzIBFgAenU3+VQpt3S6Ec8ndLo0F+Kntf6bgxbww0n/AKqlZnmWIw5Xtsbh4ywuoGGY3A5mwY+Nqq+HsqWVjLKdOFw/edm5My7hfMLYFvOy9TUHNMyOImeVgRrPdB5qgvpU+e5Y+bGjyVHZol53GGzX/Bbnil//ABKP4YN/414HFTf+Ij4YNqUMdjyFcpa6EXDDne1rfOueSzuykOB3SRc31X57j41HmPW6Hnyrah1Tip7j/wBpEcgLYM9dhz87V39qU7S/QsJquZZgSSL2taO5Hh32PzqiyXCdrioU6Bu0b9mOzfm2gf8ANXDizFmbNL9mZ0wwjRkDEEsxtZSN9WuTYD7nhetMctlZtjm5wtkfijNsRJh+zbWqsyIOzdHhlA9zvAlxawIQsw2202FaXlyEaFYAFECf3bDf9Ky+CCGTH4JYEQJeORiqsrGxu2pWY2to2sSN73N61d5frpG8vzq0jpxqk2aTkg/7NF+wv5i9TqjZammGMeCIPyFSaucwUUUUAVCzVe5fwP8AKptc8RHqQjxFQyU6YtYkXAPz9Kh45EZCttiCD5g/yNT3IDafKoOkBtJ5HlVEd0DFMsxxy/HSxu4jIDx9qUMhVdmVkjuAzMFW2rYFr9L0wYnENhDhMfHDOnYORKcQUEs8UjG0rIO8NReWO5B/2feNdfavwu40YuIbrZXI6C/1bfA7fFa+5JiY8ak0k5ffeVC3ZQRiaSFZvrjuzsU7dYtkBva+97HLJauhw46wayJFjoTqjdUVyOqtvDJ6XYof21+7SXmeFWSFlYhRbdjbugEEkX5GwNXPsr4jTTJls7CSMmUQMw2dDq1JY8tQu4H4mHQVE4iwDYSUwsSykExuftpy3/EtwreOx+1XNmhzujzPFYqfmRE6eFDEwjPZwB9faSXuWtpsg5keZ+FWOU5qXRQ+z2uL7FlFhr08wP4Xqk4mguCxJYHZd7JEotckDmTyFVeBR5HGhnXa4kI3YrsNR6KOQX0veo1U4XZXRZIXZpuSZ/8ARtccidthZb9pFa+nV7zIvUH7SdTuN76ouecHrpM2GYz4Z1sGjbU6LzFx9sKTcH3l6g86pHxgBVGYaiP69L9BUnA4+SB9cLlCTuOat+0vj+IWPnVYzpayJhLjXJ+GdMRiwY2ZR2gA90W38RbyHSlqPGNGtiGctqP1in3VuNYA3UtcLbkCvgaeRm2FnN8TA0Uh5ywXIPmbb/3lPrXaDh6JzeDGwsbW+tADAeFwQfyq0YV1yWWCk9aYlyAFl2mVfqkdhJbS7BQAV6kBgCRb3q4JmC3jvddUciqWYmxWQrbfmeW/PpT7J7OnZxJ2uFuCDfXJa45EraxI6GoWJ4JwkYAxGOw62JIWJQzXO5tqZjufw1OjfaK+TJ9r9xDy2cqZFdr6bXck21XIIGoC3oPCmXLOEu0UzYi2Hww7zO+zP4aQd1FhbUd/ujrU9cbhYDfC4Z55BylxJIA8wDv/AHVX1qDjZpcQwbEOXIN1Xki/sp4+ZufOqylCDt9kyljxvZu38I95vm/bhIoU7LCxW0JaxYjkzDoAdwp6m535LmdYzs1spGs9PLqbVYZzi2ijBUAFmC6mvpW99zaqLERo7sUYylhd1ta5XmYWI5r4eHjVY3N7S6MoSeSW8+iKMEVdNLsyuB7nPa3K/O3zApjw2E0i1yx6k8z6n414ybI1ULI1y25UkEbEbXXlqsd6Zch4fOMnEI2jFmnYfZj+6D997FR4DUegqJyeSSjEiWR5JqETvw4qYXBT4+UDvL9UD1RSQlv/AJkhv6BTSJAuLw8YxSgSCb6yUFNQXdtDPbvIWDMwbbZhv4OftHz6PFY2DLodHYwsplAdUDuu3ZIxIUFVug3Hea19hVFxYyRpMoaFZ+1VMOMMrxSiEhw8c8dhYAdmoDXa992G9d0Y0qPUXCSR04D+vxEmKZQgREijUXIUAKLC9zsqj4uaf4Vvb8R/l+pNLfDGWdjDHEBuN282PP8Ah6Cm7IYe1xUajlrH91N/zsfnWb5OxrSNM1FBYW8K9UUVscYUUUUAUUUUBR42ICQj1I/WqfFj57EUyZrBcAjxtS3jlA0gHe3LxFZvhnXidkSbCI6MpJZXBVlPUEbg1lWPyL6HjEhxJYYdnR7r9qK9iwH3lBYHa438a1KVyp2/r0pe4oyr6ZHpZu8vuMfsn+B6ipNMmPdWhf4ljUYNHieFPo6wlZ4yLGZRIHijZRqlkciGW5uEubkcqv8AJuII84wjQYj6vFw7ttZlcXAkRT06Mh8SDsRWeYHPnwcqYbFoiGB5GSVkLvDrAZjEt9DFiqlWYHSWvVtnmWEyRz4T6jEKI5N2YMI5FBQYl5DpbEO5Kjfvh7kAWqzRxd8M443AvHI0E6jUB/ysvRkvzU/MHnvX3C4FcPCxRSbb28ztf0H7qZMlzyDNE7DEr2OJS+3IhhsTGT6bofzG9esbk74fuyWK9JFHdPqPsnyO3ma5JY3Hrr4OWWDXldCHigLHvhgbO5tvq+yoP9da+w5i6oC1n1arACxBG7XJ6CrvNcoVlsvctuLcr+Yqlx+GkJ0aS26lHuBpO2on4gmrbRlwRcXwyThc2QkWax22O3MA/HnV7g50bZtN/O376V8PEHnlcgEKVVfUcyK8Kb4mRyoZUAFyeRAJG3Xeqaq+DPRXwO0uXRWJKJ6kCoLKiEAaVvyAsL+gqPNDZQLagwgYgnmxLfryrxh8qSXDKri9i1iL3Q6jYA8xbaqZIUrbOfNipW2cJs/gViC+4JBsDYHkbm3Lcb+dU+Y5nJKiaQVV9QIU97WhuU1D7yja3Wo2GXsowxQuF7eGYLzuSCG/QfCpGByWQLEdelSUkdSNw68reFxa9XUIY+Syhjx8/wCQyzNAiEOkhiZiY2Ya+6eQPxFWEGU2lEjOzadRRTsF1eQ/TyqVhsMsYIXYElrdLnc28B5VaZDkk2Nb6kaYwbNOw7g8Qg/2jeQ2HU9Kytzl6DG5ZJNY13/78HHAYOSeUQwqGkIvv7qL1dyOSjw5sdh5MHFXECZThlwOCOvGTEXc21BnsvaP0DHYKvJQB0Avw4k4zw2TwthcEBJiT77tZrNa2qVvtP4INh5DYo/CuKE3al1ilxryCQnGe7LDbvqkjEdm4N31bEhe6QVs3ZixLGvuejgwLEvudcF2uWrO8cseKiDrFi411qyPdgpDsA1rhwJFuL7MNwK85J2mNxJxU7O6x9yLtCC2kX0gkAA6QeYHM+VfM1zCTH4qeCFlOG7Us0ojVXlVSwiaVwAXaxNibXJud6ccmyxUVQBZE2H9f1zq8nR6GGH6n0Too9CFj7x2HkT/AAFN3s7y3d5iNh3F9ebfIWHzpaWJpZFjQXZjYDzP7hzPkK1TK8vWCFI15KLX8TzJ+JuarFW7JyzJdFFFanMFFFFAFFFFAeZEuCDSvmmXEMNtwSV8LbXHxpqrhi8KHW3Xoaq1ZeE9WIc/l4/KomLiKrdRsevgRV9j4dPaXG99v6+NQUYWseXI1Q74y4sSeJuG1x8AVu7Ol+ykt05lH8V6jwN/G1ZficwxWGvh5GZQNd0IBDawFJN9nFlWxN7WFrVu2Ky3Rex66gaXeI+Ho8WmmVdLrcK67H4fw5VZMpkxKfqj2KGQcNCTDxSam7Z+2lUrdnYArHEoF9ryA3Y/eXzs6ZfxdJEujFr2qXKdqveBt7wv7r+o/OkTD5biMAzA3aF9IcqSA6g30sR3lvc/PrTXhc3jxDYZXKRhH1OhBKm5jjRETwIvcchdjUs5argtMRkkM668JIBzuvNflzT+tqXMxy+aI/WxMF+8veX1uOXxtVNjZjHPpw4dCp0CzEsWB072tuT0G1TMB7RcWrdm6Cc7i2kh7jmO7zOx6Vm8akZSxwn2ckZDfRbc72t6dK7Zfli3fn3yS3x2qYnG+XzkfSMOVPjpDfJl71X2TrlEhGmcx+WuVf8AMDWfktdMwfh3+lkfBZABHZmYnUhvtfu+6PTc1Hx+UWl7RXZVLamQcif508iDKgP9bP8A9U/uFQMzzHJIlu7GXyvO9/hcCjxTfbMpYMj7Yg4mdE5lVJ6bXJ9OZNScBw/ip7GKBwp+3L9Wnr3u8R6Kasx7U8FG2jLsveRzy0RohP8AcDOapX9omY40S6HhwMUbIjsQ5YO5YIl7M5Y6W91RbSaR8Ml2yI+CgvqdlziOG8LggJMynV+ojFwh8gnvyfHbyquzT2hYnHKY8vQ4bDI0aST2F0VzpU2X+zXn7u9hzFVDcFrLBqlkkkxcizBTJIATiIm3hEbLqa8dn1My/wBolhc2MjPOL8LDK7YcXkkjQOIlVYnR0DoNibSwkgatPeGpWHMnojFR4R2Rioqkj7LwfhkiaCU6WQFpcToHMmRopO0eQfVMgVezVS2oODvalCJcTmLxh2LLDGkQYgAJGt9K7AXO586vosixGPcT409nH3iqKLGzMXIRT7qlmY79SabMuyhVUKihEHIfz8aOVHTjw3zLo85FlKQxCOMbc2PUn18atJpbbD0AHjXREC7VfcL5GMTJrK/Vodz94/dHl4/LrWXfCNpySRacB5AUBxEo7zbRjwTqfVv0A8aca+KK+1slRxN27CiiipICiiigCiiigCiiigIWZZeJF/F+vlSvLhOY8zcHnfpTrVVnOUdoNS7OPz/nVJRs2xzrgVRHsQelv1vUWfDhxYnf95NTXBW9/QjwriEAa/IGszrTKabC6feFx+RHmKo8ZwbG5vE4iY725r8unw+VObrub8h8jUOXBK247p8qtYdSXqMvzDIMZhn1hSdJuJIu9a24PiPiKo8BnRineZtRl0ylT1ErAgMb+Gpj62rZhBIvKxqrzHLIpf7aFW8yov8AMb1ZSMXg/wBrFfDZph3EghKL/YhFdo0OkmaaW3bKyn6yULba4TnXrDzJ/o+EiOHtZHn1MEUOFTstG68rsX3PMVLn4HwpOwdP2WP6MDXaPhGAADt3Xc81U9Da9rUso8My+xmCwixPKqodMfbqpN7rMrxxJa/2JADbz3pV41kWWCEosCAQLI4QIp1l2jYc9ROynR0FzQch3sHJF+ZX+dcMw4XUue+7JewNgL+dul6bDyJkD/ptpTCo817xYkTEx6gjO2lF7NSgICwwna477bG5FUy8SKmJxIwsAbDzOrCFtYIKHVGymNgyMCWtZtgxG9M2F4MhtugLb21G+w8uVXOE4dCiwAUeAA/dUbfBdeGf6mJmJwmNxzFsQ4jRmDaRsAQojBCDqEVVuTchRcmr/IeFIoiCi63H236enQfrTJFlKLz39a7k2AsLCobvs1jjhHo5pCARfvN+Q+Fe2l3tyry2KWPc7ncWH8a9ZFlMuNl0R3WMf2j9FHgPFj0Hx5VTsSlXJY8PZO2Kk0gWjW3aP4eQ/Efy5+FadhMIsSKiAKqiwA6VyyvK48PEscS6VX5k9ST1J8al1tGNHFOezCiiirFAooooAooooAooooAooooAooooCszXJxJcrs36+tK0+HKnSQVYeNPlcMVgkkFnUH9R6GquNmsMjjwIay9OR5VweEA+Hz/jyq8zfhKS5aBg34W2PwPI/G1UGZQOo76lWtyIrN8HVGUZdM4aBe5fQfW4NdZgQALg3uar4YC3kPGpOOxIVdI9P51FmrXsfWQbbA/0TXLsb/ZqAspHI2qxw8mpbnnQNanB4wBax8LV57ICwtbxva1ecTmRvYW28ahSYsnr8qEpNlhJAL32G1vGvmkeJ+FVk0zLbfnUpcdyHU8h50KtNErWOWm/nVdmOahe6tifyHr/AAq5i4Xxs4AjQRg83lOmw8l94n4WpgyL2VYeI6p2OIfwPdT+6Dc/En0qVFmTyRXYl8McMzY57glYge9IRt6IOrfp1rYMryqPDxLFEulV+ZPUk9SfGpMMKooVQFUbAAWAHkBtXutEqOWeRzYUUUVYzCiiigCiiigCiiigCiiigCiiigCiiigCiiigCuc2HVxZlDDwIuPzrpRQFJi+EoWuV1Rn8JuPkaoJfZ49zaZW/aUg/kTT1RVdUaRyyj0zNZ/Z/ir7GH4M371rqeDMUEsFS/7f8q0WimiL+fIy4cAYtjusa/8Amfyr7B7L8QT3pYlHkWP7hWoUVGiHnzEvB+zKIG80jyHwWyD95/OmbL8jhgH1Uap5gb/Fjv8AnU6irJJGbnJ9s+Wr7RRUlAooooAooooAooooAooooAooooAooooAooooAooooAooooAooooAooooAooooAooooAooooAooooAooooAooooAooooAooooAooooD//2Q==

It might really make a difference 😉

RodhasGibson

Well-known member

Al ears

Well-known member

gbhsi1 said:Highfield said:I keep bees in my audio equipment. The waxy hive protects the sensitive circuit boards whilst protecting the surfaces from sea salt when I take my amplifier diving. One thing though, despite cleaning the ground contacts I now have an 'orrid buzzing noise ...

ha ha :clap:

Could this be in any way related to humming turntables I wonder gbhs1??

A

Anonymous

Guest

Highfield said:I keep bees in my audio equipment.

I think you'll find WASPs are better for speaker placement though

TRENDING THREADS

-

-

-

-

-

-

-

Excellent sound quality in a system is enough for most people with neighbours

- Started by Snooker

- Replies: 38

Space.com is part of Future plc, an international media group and leading digital publisher. Visit our corporate site.

© Future Publishing Limited Quay House, The Ambury, Bath BA1 1UA. All rights reserved. England and Wales company registration number 2008885.