Hey there,

Before I start, may I just explain that my understanding of audio technology is pretty limited. I’ve taught myself the basics but, as this is for a one-off project rather than the beginnings of a hobby, I don’t know much more.

Right, let’s get into it…

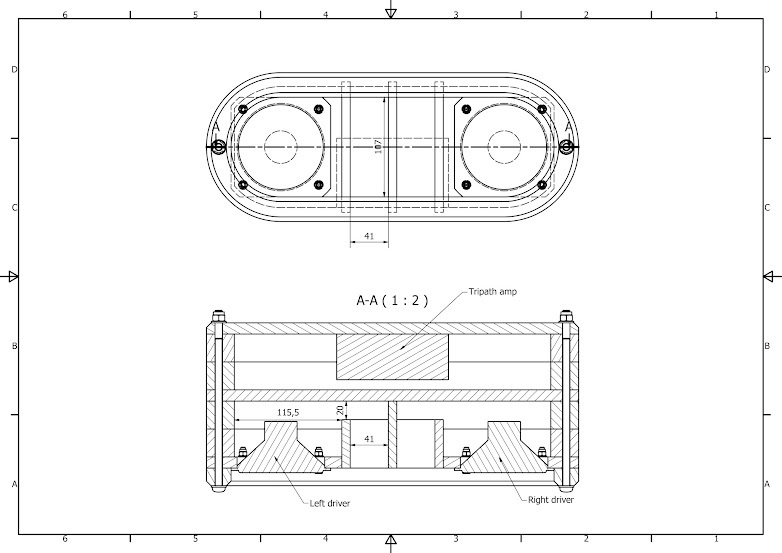

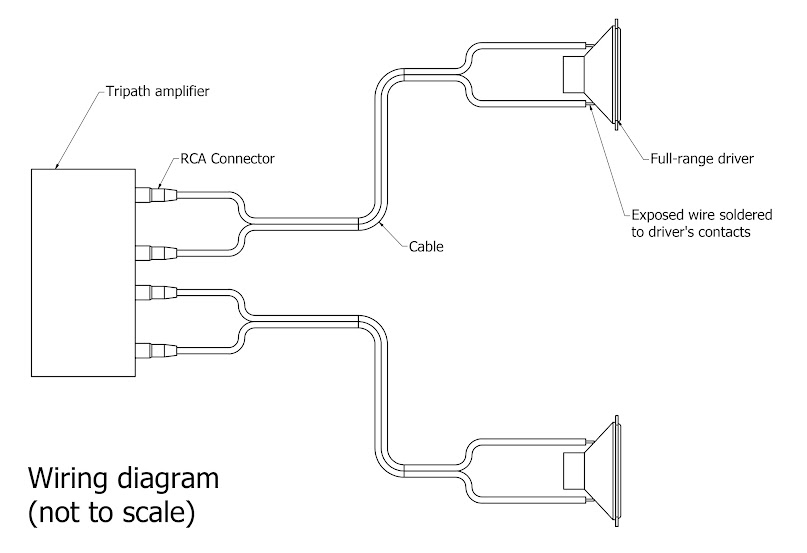

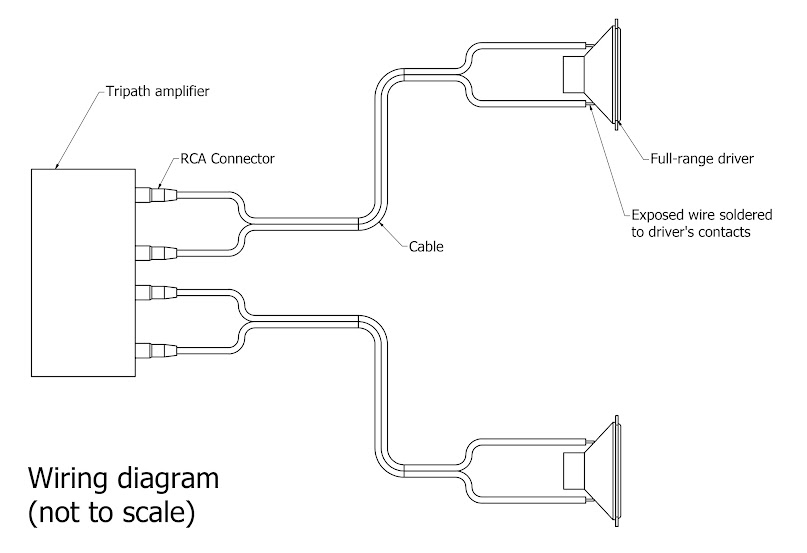

I need to wire a 15W Tripath amp to a pair of 4” 10W full-range drivers. The amp has RCA sockets on the back whilst the drivers just have positive and negative soldering contacts. My plan is to cut a metre-long RCA cable in half and strip the rubber insulation off the exposed ends. This will provide me with two 50cm cables with RCA connectors on one end and exposed wire on the others. I will then solder (and seal with heat-shrink) the two exposed ends of each 50cm cable to the two solder contacts on each driver. The RCA connectors on the other end of each cable will just go straight into the sockets on the back of the amp.

Will this work? Up to now, I have just assumed that RCA cables are simply insulated wire with special connectors on each end but, thinking about it, it was stupid to assume this. Are RCA cables instead made up of a group of different wires? Will there be other complications in my plan that I haven’t even thought of?

Any advice would be greatly appreciated.

Thank you all in advance,

Isaac

PS: I'm using Cambridge Audio 100 Series cables.

Before I start, may I just explain that my understanding of audio technology is pretty limited. I’ve taught myself the basics but, as this is for a one-off project rather than the beginnings of a hobby, I don’t know much more.

Right, let’s get into it…

I need to wire a 15W Tripath amp to a pair of 4” 10W full-range drivers. The amp has RCA sockets on the back whilst the drivers just have positive and negative soldering contacts. My plan is to cut a metre-long RCA cable in half and strip the rubber insulation off the exposed ends. This will provide me with two 50cm cables with RCA connectors on one end and exposed wire on the others. I will then solder (and seal with heat-shrink) the two exposed ends of each 50cm cable to the two solder contacts on each driver. The RCA connectors on the other end of each cable will just go straight into the sockets on the back of the amp.

Will this work? Up to now, I have just assumed that RCA cables are simply insulated wire with special connectors on each end but, thinking about it, it was stupid to assume this. Are RCA cables instead made up of a group of different wires? Will there be other complications in my plan that I haven’t even thought of?

Any advice would be greatly appreciated.

Thank you all in advance,

Isaac

PS: I'm using Cambridge Audio 100 Series cables.